When using a gland packing, attention must be paid to its running-in charac-

teristics. It may take hours or even days for the amount of leakage to reach

constant levels. After every start-up of the shaft or re-tensioning of the gland

packing, be sure to wait a fairly long time before further adjustments are made.

The resulting amount of leakage must be sufficient to keep the temperature

around the shaft seal within the permissible range.

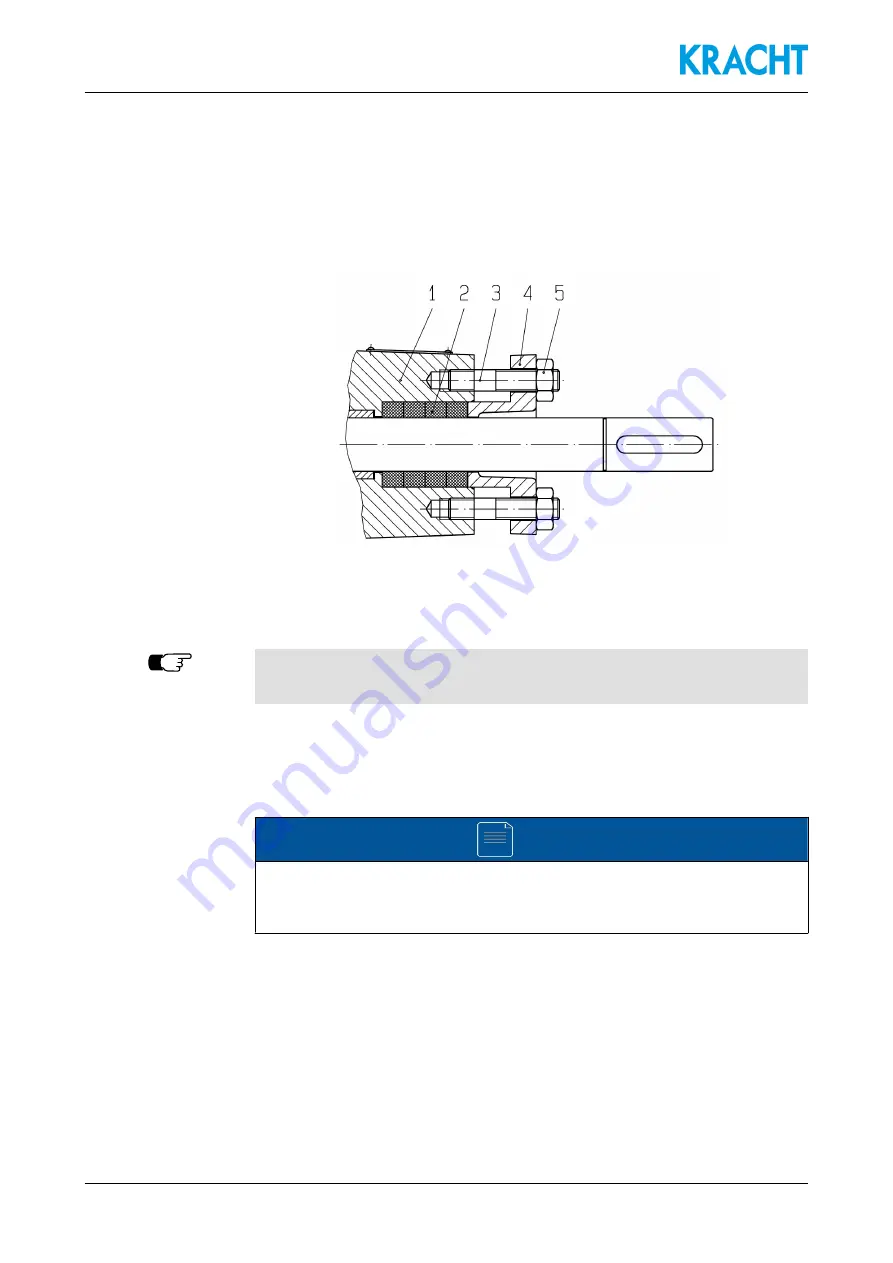

1. Gland cap

4. Gland follower

2. Packing ring

5. Hexagonal nut

3. Stud bolt

1.

Untightening the hexagon nuts will increase the amount of leakage.

2.

Tightening the hexagon nuts will decrease the amount of leakage.

The amount of leakage will typically be higher after a disturbance (e.g. unit

turned off and on again or after pressure/temperature fluctuations). In this

case, the gland packing should not be retightened until the amount of leakage

has reached a constant level.

NOTICE

Seal failure

Dry running will cause the seal to fail.

1.

Make sure there is sufficient leakage from the gland packing.

7.4

Further operation start-up

●

Open existing shut-off elements upstream and downstream of the de-

vice.

●

Adjust pressure relief valves in the system installed for lowest opening

pressure.

Gear pump BT / BTH

88026290002-04 2021-02-05

41