8

Start up

1. Check if required pressure has been reached within the installation (see section

"Technical Data"). In order to check it use

or

button when control panel

is „on’’.

Flashing A symbol (see section "Failures") indicates too low installation pressure.

Above description does not apply to open type installations.

2. Set the pump at constant mode (see section "Advanced settings”).

3. Switch the boiler on (press

button).

4. Check if the appropriate medium flow rate has been reached (the „H” indicator is

on with a constant light). The pump should get vented itself after a short working

time, however, if necessary, vent the pump in the following way:

•

close the cut-off valve on the outlet,

•

set the pump on the highest efficiency (see section "Advanced settings”),

•

let the boiler with the pump on run for 15-30 s.

•

open the cut off valve.

5. Switch the boiler off (press and hold

button for 3 seconds).

6. Set the pump at automatic mode (see section "Advanced settings”).

7. Connect programmed room thermostat.

8. Switch the boiler on (press

button).

9. Set parameters of heating curve adjusted to the building (heating curve coefficient

and offset) - see section "Advanced settings".

Reset of the curve slope switches off weather compensation and starts boiler's

operation in accordance with manual adjustments of the installation.

Содержание EKCO.L2M

Страница 1: ...Electric Central Heating Flow Boiler EKCO LN2M EKCO L2M Assembly and operating manual...

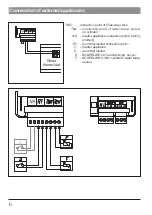

Страница 18: ...18 Connection of three way valve diagrams AZV 642 PUMP TWV AZV642 valve connection diagram Brown Blue Black...

Страница 19: ...19 GB 096B_f PUMP TWV Honeywell valve connection diagram Brown Blue Black...

Страница 20: ...KOSPEL S A 75 136 Koszalin ul Olchowa 1 tel 48 94 31 70 565 serwis kospel pl www kospel pl...