Foreword and general information

Explanation of terms for maintenance standard

PC800, 850-8E0

Explanation of terms for maintenance standard

00-19

(Rev. 2010/03)

The maintenance standard chapter explains the criteria for replacing or reusing products and parts in the ma-

chine maintenance work. The following terms are used to explain the criteria.

1.

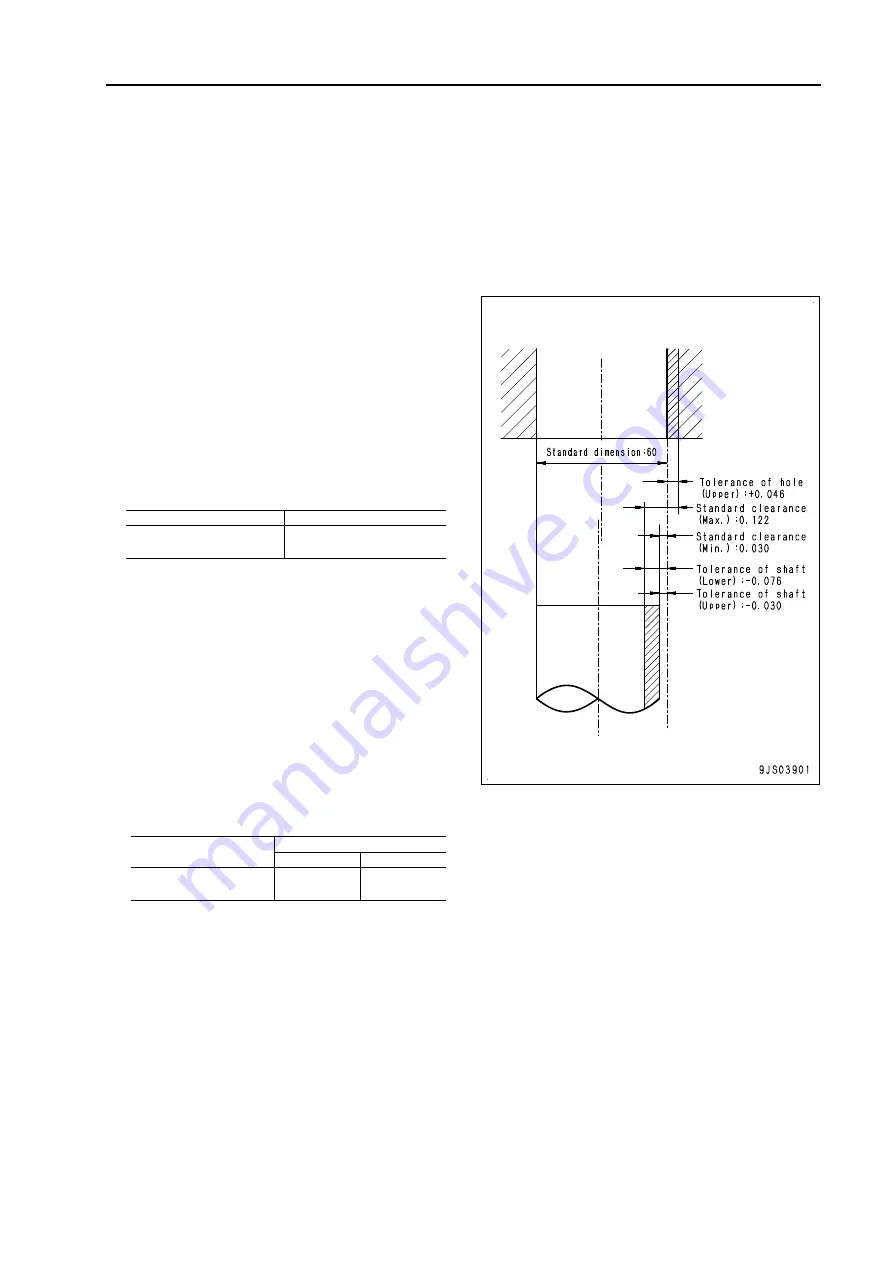

Standard dimension and tolerance

q

To be accurate, the finished dimension of

parts is slightly different from one to another.

q

To specify the finished dimension of a part, a

certain dimension is set for the part and an al-

lowable difference from that dimension is in-

dicated.

q

The above dimension set is called the "stan-

dard dimension" and the range of difference

from the standard dimension is called the

"tolerance".

q

The tolerance with the symbols of + or – is in-

dicated on the right side of the standard di-

mension.

a

The tolerance may be indicated in the text

and a table as [standard dimension (upper

limit of tolerance/lower limit of tolerance)].

Example) 120 (–0.022/–0.126)

q

Usually, the dimension of a hole and the di-

mension of the shaft to be inserted into that

hole are indicated by the same standard di-

mension and different tolerances of the hole

and shaft. The tightness of fit is decided by

the tolerance.

q

Indication of dimension of rotating shaft and

hole and their related drawing.

2.

Standard clearance and standard value

q

The clearance made when new parts are as-

sembled is called the "standard clearance",

which is indicated by the range from the min-

imum clearance to the maximum clearance.

q

When some parts are repaired, the clearance

is generally adjusted to the standard clear-

ance.

q

The values indicating performance and func-

tion of new products or equivalent are called

the "standard value", which is indicated by a

range or a target value.

q

When some parts are repaired, the value of

performance/function is set to the standard

value.

3.

Standard interference

q

When the diameter of a hole of a part shown

in the given standard dimension and toler-

ance table is smaller than that of the shaft to

be inserted, the difference between those di-

ameters is called the "interference".

q

The range (between A and B) from the differ-

ence (A) between the minimum dimension of

the shaft and the maximum dimension of the

hole to the difference (B) between the maxi-

mum dimension of the shaft and the mini-

mum dimension of the hole is the “standard

interference”.

q

After repairing or replacing some parts, mea-

sure the dimension of their hole and shaft

and check that the interference is in the stan-

dard range.

Example:

Standard dimension

Tolerance

120

-0.022

-0.126

Example:

Standard dimension

Tolerance

Shaft

Hole

60

-0.030

-0.076

+0.046

0

00-19