- 15 -

KD 477-2 Workshop Manual_cod. ED0053029370_

1° ed

_ rev.

00

VIII

(*)

(*)

(**)(***)

(x)

(xx)

8

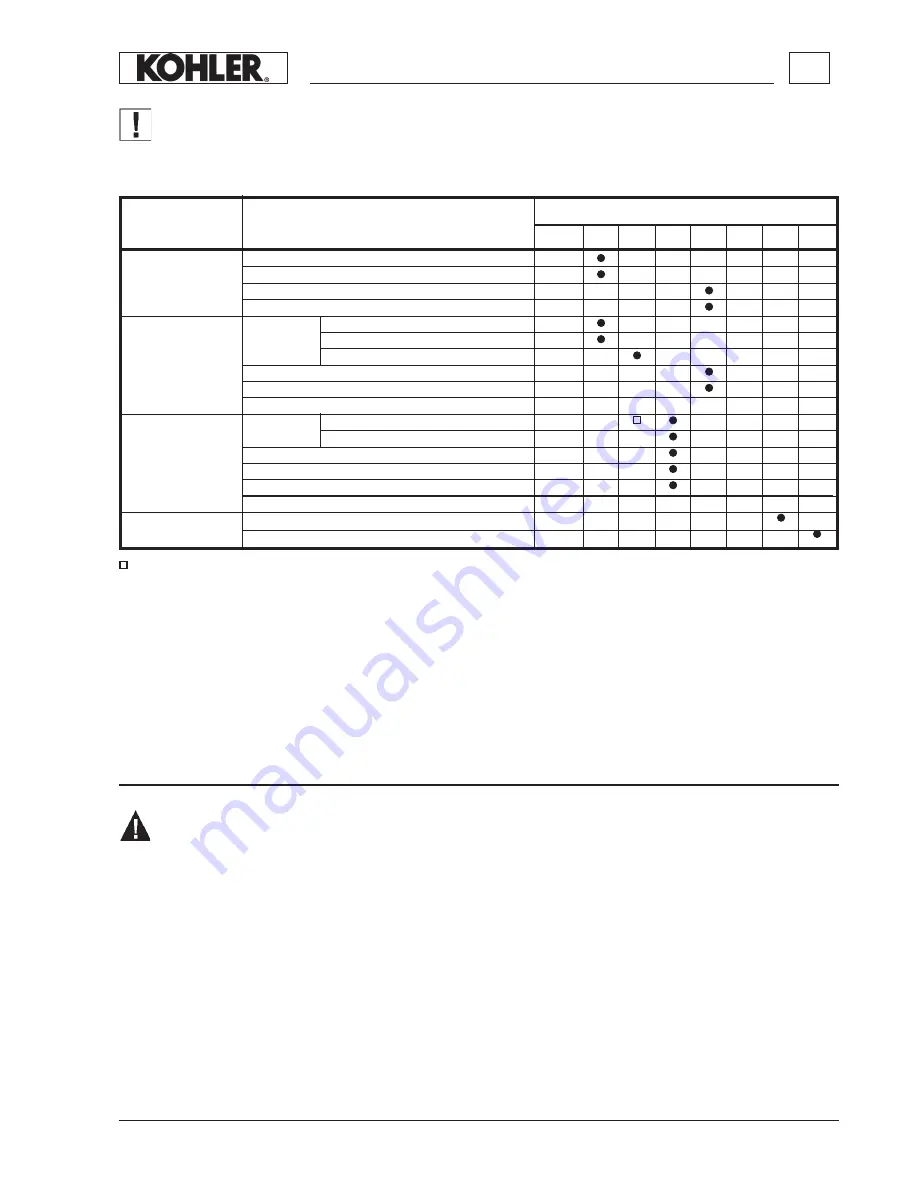

50 200 300 500 2500 5000

Failure to carry out the operations described in the table may lead to technical damage to the machine and/

or system

First replacement

(*)

Under severe working conditions, clean daily.

(**)

Under extremely dusty conditions, change every 4-5 hours.

(***) See recommended oil type.

(x)

The partial overhaul includes the following operations: valve and seat lapping, injector and injection pump overhaul,

injector projection check, fuel injection spark advance check, check of the harmful area between head and piston,

camshaft and crankshaft end float check, tightening of bolts.

(xx) The general overhaul includes - in addition to all partial overhaul - the following procedures: cylinder and piston repla-

cement, seat, guide and valve refacing, crankshaft replacement or grinding, bench bearing and connecting rod replace-

ment.

To avoid explosions or fire outbreaks, do not smoke or use naked flames during the operations.

Fuel vapours are highly toxic. Only carry out the operations outdoors or in a well ventilated place.

Keep your face well away from the plug to prevent harmful vapours from being inhaled. Dispose of fuel in the correct

way and do not litter as it is highly polluting.

FUEL

When refuelling, it is advisable to use a funnel to prevent fuel from spilling out. The fuel should also be filtered to prevent dust or

dirt from entering the tank.

Use the same type of diesel fuel as used in cars. Use of other types of fuel could damage the engine. The cetane rating of the

fuel must be higher than 45 to prevent difficult starting. Do not use dirty diesel fuel or mixtures of diesel fuel and water since this

would cause serious engine faults.

The capacity of the standard tank is: lt. 7.0

The maintenance operations listed above refer to an engine operating in normal conditions (temperature, degree of humidity,

dust in the working environment). They may vary significantly according to the type of use.

MANUTENANCE

INTERVAL (HOURS)

COMPONENT

OPERATION

CLEANING

CHECK

OVERALL

INSPECTION

REPLACEMENT

OIL-BATH AIR CLEANER

HEAD AND CYLINDER FINS

FUEL TANK

INJECTOR

AIR CLEANER OIL

LEVEL OIL SUMP

BATTERY FLUID

VALVE/ROCKER ARM CLEARANCE

INJECTOR SETTING

AIR CLEANER

SUMP

EXTERNAL OIL FILTER CARTRIDGE

FUEL FILTER CARTRIDGE

DRY AIR CLEANER CARTRIDGE

PARTIAL

COMPLETE

OIL

MAINTENANCE - RECOMMENDED OIL TYPE - REFILLING