7

19 590 02 Rev. A

KohlerEngines.com

EN

Fuel Recommendations

WARNING

Explosive Fuel can cause fires

and severe burns.

If a gaseous odor is detected,

ventilate area and contact an

authorized service technician.

Propane is extremely flammable and is

heavier than air and tends to settle in low

areas where a spark or flame could ignite

gas. Do not start or operate this engine in

a poorly ventilated area where leaking gas

could accumulate and endanger safety of

persons in area.

To ensure personal safety, installation and

repair of propane fuel supply systems must

be performed only by qualified propane

system technicians. Improperly installed and

maintained propane equipment could cause

fuel supply system or other components to

malfunction, causing gas leaks.

Observe federal, state and local laws

governing propane fuel, storage, and

systems.

This engine is certified to operate on

commercial propane (per GPA STD 2140). If

you have any questions, contact your propane

supplier.

Propane from an appropriate propane fuel tank

(supplied separately) is required to operate this

engine.

Vaporizer/Regulator

In compliance with government emission

standards, vaporizer/regulator is preset

at factory to provide proper supply of fuel.

No adjustment or resetting of vaporizer/

regulator is to be made. All service relating to

vaporizer/regulator must be performed by a

Kohler authorized dealer or qualified propane

personnel only.

Vaporizer/regulator can change propane from

supply tank to a gaseous/vapor state.

Lock-Off assembly opens and closes controlling

fuel flow from supply tank before reaching

vaporizer/regulator.

Over time, fuel deposits can accumulate inside

vaporizer/regulator. Removing these deposits

is recommended. Follow steps below to drain

vaporizer/regulators.

1. Turn fuel supply valve off, run engine out of

fuel, and turn off ignition switch.

2. Disconnect and ground spark plug leads.

3. Remove drain plug from bottom of vaporizer/

regulator. Remove any accumulated

deposits.

4. Reinstall plug and tighten securely. If

required, a replacement plug can be found at

KohlerEngines.com.

Fuel Line

High pressure fuel line meeting a minimum of

SAE R7 standard must be installed on Kohler

Co. engines equipped with propane EFI system

(from vaporizer/regulator to injectors).

Spark Plugs

CAUTION

Electrical Shock can cause injury.

Do not touch wires while engine

is running.

Clean out spark plug recess. Remove plug and

replace.

1. Check gap using wire feeler gauge. Adjust

gap, see specification table for adjustment.

2. Install plug into cylinder head.

3. Torque plug to 20 ft. lb. (27 N·m).

Jump Starting

Follow all safety guidelines and procedures

provided by battery manufacturer and/or

original equipment manufacturer (OEM). Failure

to follow proper procedures may result in

serious personal injury and/or non-warrantable

damage to engine’s EFI components.

Electronic Fuel Injection (EFI) System

EFI is an electronically-controlled fuel

management system which is monitored by an

Electronic Control Unit (ECU). A Malfunction

Indicator Light (MIL) will illuminate if problems

or faults are detected. Servicing by a Kohler

authorized dealer is necessary.

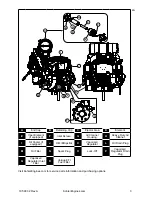

Fuel System Components

Engines are equipped with special EFI fuel

filters. See Maintenance Schedule.

Fuse Replacement

This engine has three (3) blade type automotive

fuses. Replacement fuses must have same

rating as blown fuse. Use fuse chart below to

determine correct fuse.

Wire Color

Fuse Rating

2 Solid Red Wires

10-amp Fuse

1 Red Wire with Black Stripe

1 Red Wire with White Stripe

10-amp Fuse

2 Purple Wires

30-amp Fuse