10

Water Screen

CAUTION:

If the screen is not kept clean, the

flow of water to the pressure washer will be

restricted and the pump may be damaged.

The pressure washer is equipped with a water

inlet screen to protect the pump. Clogging of the

water screen will restrict flow of water. Cleaning

is immediately required with unit turned OFF.

1. Disconnect the garden hose from the INLET.

2. Remove the water screen from the INLET.

3. Clean screen under warm water.

4. Replace screen immediately to prevent any

foreign matter from entering the pump.

5. Reconnect the garden hose to the INLET.

CAUTION:

Do not damage the screen while

removing or cleaning. Any foreign particles

entering the pump will damage the unit.

Basic Maintenance

– continued

Nozzle

Clogging of the nozzle causes pump pressure to

be high and a distorted spray pattern can result.

Cleaning is immediately required with unit turned

OFF.

CAUTION:

Failure to discharge the residual

pressure could result in personal injury due

to discharge of high-pressure water

1. Disconnect the nozzle from the lance.

2. Flush the nozzle backwards with water.

3. Reconnect the nozzle to the lance.

Restart the pressure washer and depress the

trigger on the spray gun. If the nozzle is still

plugged, repeat steps 1-3.

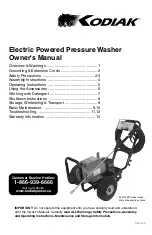

Step 4.

Remove the yellow oil fill plug from pump.

Step 5.

Add oil (SAE30 non-detergent motor oil)

until the oil level is halfway up the oil sight

glass.

Step 6.

Replace yellow oil fill plug securely.

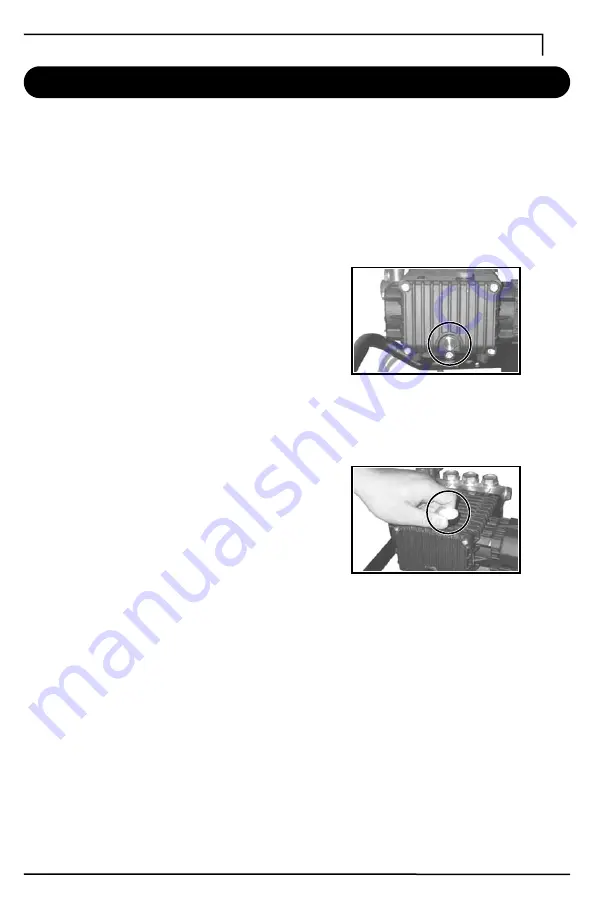

Step 1.

Use a socket wrench to remove the drain

plug, located on the side of the pump.

Step 2.

Drain the oil into a suitable container.

Please dispose of oil properly.

Step 3.

Replace the oil drain plug securely.

Pump Oil Change

NOTE:

Check the pump before every use as well

as the system components. Check Pump oil level

daily. The pump of the pressure washer will

require an oil change once a season or after the

first 50 hours operation and then every 50 hours

after that. Use only SAE30 non-detergent oil

in the pump. The pump also contains an oil sight

glass and a dipstick.