30

OPERATING INSTRUCTIONS

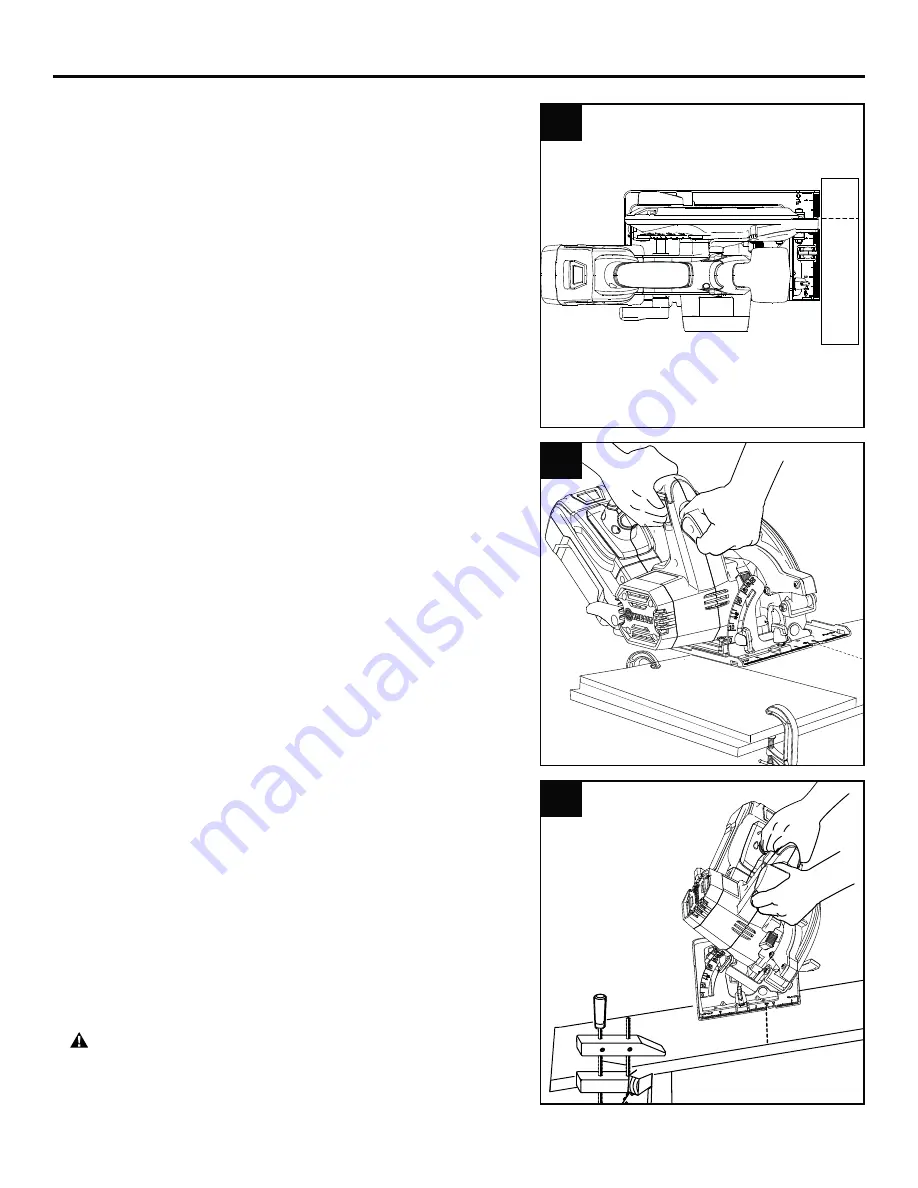

Cross-cutting/rip cutting (Fig. 12-13)

When making a cross-cut or a rip cut, align the guideline

with the blade-guide notch (T) on the base, as shown in

Fig. 12

. The distance from the saw blade to the saw

base is approximately 1-1/2 in. (3.8 cm) on the left side

of the saw and 4-1/4 in. (10.8 cm)

on the right side.

Blade thicknesses vary, so you should always make a

trial cut in scrap material along a guideline to determine

how much the guideline must be offset from the guide to

produce an accurate cut.

NOTE:

The distance from the cutting line to the guideline

is the amount by which the guide should be offset. Use a

guide when making long or wide rip cuts.

Rip cutting using a straight edge:

1. Secure the workpiece.

2. Clamp a straight edge to the workpiece using

C-clamps (not included).

NOTE:

Position the C-clamps so that they will not

interfere with the saw housing during the cut.

3. Press the lock-off button and depress the trigger switch

to start the saw.

4. Allow the blade to reach full speed, then guide the saw

into the workpiece and make the cut.

5. Saw along the straight edge to achieve a straight rip cut.

6. Release the trigger switch and allow the blade to come

to a complete stop.

7. Lift the saw from the workpiece.

NOTE:

Do not bind the blade in the cut.

BEVEL CUTTING (Fig. 14)

To make the best possible cut:

1. Align the cutting line with the blade-guide notch (T)

on the base when making 45° bevel cuts.

2. Make a trial cut in scrap material along a guideline

to determine the amount to offset the guideline on

the cutting material.

@ Q"

between 0° and 50°.

WARNING:

Attempting a bevel cut without having

the bevel-locking knob securely locked in place can

"

12

12

14

13

13