Page 4 of 12

0901177 Rev: A (10/15)

INSTALLATION

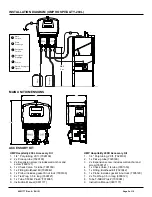

Mount the unit (using suitable hardware) with the

provided bracket in the accessory kit. Try to keep the

unit within three feet from the final rinse line to avoid

long tubing runs.

CAUTION: Do not mount the unit in the direct path

of steam. This can short circuit and permanently

damage the unit. Mounting the unit on the side, on

the back, or on the vents of the dishwasher may

cause thermal overload and damage or hinder the

performance of the unit.

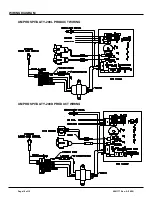

Check all applicable plumbing and electrical codes

before proceeding with the installation. This will help to

ensure that the system is installed in safe and suitable

manner. A wiring schematic of the dishwasher should

be used as reference for making electrical connections

— this is typically provided by the dishwasher

manufacturer if one cannot be located on the machine

itself.

Rinse Plumbing

(1) Install the provided 1/4" tube x 1/8" NPT injection

fitting into the side or bottom of the dishwasher

rinse line between the rinse solenoid valves and the

rinse jets. If necessary, drill a 11/32" hole and tap to

1/8" NPT. Use of a saddle clamp may be desired on

copper rinse line for better support.

(2) Cut a suitable length of 1/4" OD poly tubing and

connect between the discharge (right) side of the

rinse pump’s squeeze tube and the injection fitting.

Cut 2” of the supplied T-50EH tubing (7018061)

and zip tie the tubing to the pump suction and

discharge fitting. (See Diamgram A below). Use

the T-50EH tubing to connect poly tube to the pump

fitting.

(3) Cut a suitable length of 1/4" OD poly tubing and

connect between the suction (left) side of the rinse

pump’s squeeze tube and the pickup tube provided.

Be sure to draw tubing through the end of the

pickup tube.

(4) Hand-tighten the compression nuts on both the

rinse fitting and pickup tube. Plastic ties can be

used to cinch around the connections where the

poly tubing is inserted into the pump’s squeeze

tube.

Liquid Detergent Plumbing

(1) Install the provided bulkhead fitting through a wall

of the wash tank (above water level). If an existing

mounting hole cannot be located, use of a 7/8" hole

saw or punch may be desired.

(2) Cut a suitable length of 1/4" OD poly tubing and

connect between the discharge (right) side of the

detergent pump’s squeeze tube and the bulkhead

fitting.

(3) Cut a suitable length of 1/4" OD poly tubing and

connect between the suction (left) side of the

detergent pump’s squeeze tube and the pickup

tube provided. Be sure to draw tubing through the

end of the pickup tube.

(4) Hand-tighten the compression nuts on both the

bulkhead fitting and pickup tube. Plastic ties can be

used to cinch around the connections where the

poly tubing is inserted into the pump’s squeeze

tube.

Dry Detergent Plumbing

(1) A powder or solid type feeder (not provided) should

be used for dispensing dry detergent products.

Follow the instructions included with the detergent

feeder for installation, and recommended water

temperature/pressure.

(2) Cut a suitable length of 1/4" OD copper tubing (not

provided) and connect between the input side of the

water solenoid and the water source. Maximum

recommended water temperature is 140°F (60°C).

(3) Cut a suitable length of 1/4" OD copper tubing (not

provided) and connect between the output of water

solenoid to a powder or solid detergent feeder.

(4) Carefully tighten the compression nuts on the water

solenoid — over tightening may cause solenoid to

leak. Tighten connections to the water source and

detergent feeder as needed.

INSTALLATION

Diagram A

Содержание UMP Hospitality

Страница 9: ...0901177 Rev A 10 15 Page 9 of 12 PARTS DIAGRAM ...

Страница 11: ...0901177 Rev A 10 15 Page 11 of 12 NOTES ...