Diaphragm

–Liquid pump NF 10

Servicing

KNF Flodos AG BA_NF10_EN_05_069219

Operating and Installation Manual

18

8. Servicing

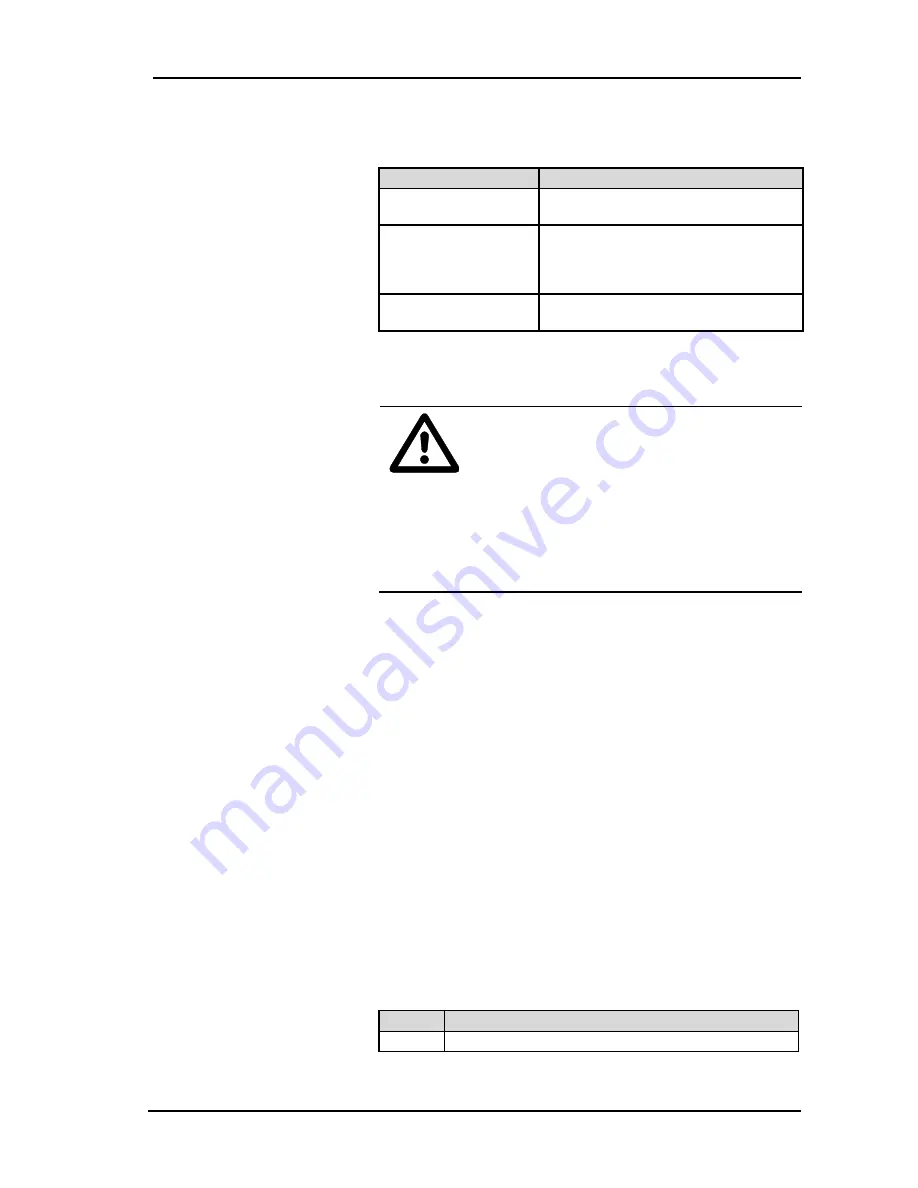

8.1. Servicing schedule

Component

Servicing interval

Pump

-

Regular inspection for external

damage or leaks

Pump head

-

Clean the pump internally: if the

flow rate changes, the pump does

not pump or no vacuum is created

(section 8.2)

Diaphragm and valves

-

At the latest change when the flow

drops off

Tab. 14

8.2. Cleaning

WARNUNG

Health hazard due to dangerous substances

in the pump!

Depending on the substance transferred, caustic

burns or poisoning are possible

Wear protective clothing if necessary, e.g. pro-

tective gloves.

Rinse the pump with a neutral liquid and pump

empty.

8.2.1. Flushing the pump

When pumping aggressive media, KNF recommends flushing

the pump with a neutral fluid under atmospheric conditions for

a few minutes before switching off, to extend the service life of

valves and diaphragm.

8.2.2. Cleaning the pump

Wipe the outside of the pump with a soft dry cloth. Ensure that

any cleaning solvents used will not damage the materials of

the pump head and crankcase housing (check material

resistance properties).

If there is compressed air available, blow off the separate

parts.

▪

Pump must be switched off and mains plug removed from

the socket.

▪

The pump must be free of any hazardous substances.

▪

Hoses must be disconnected from the pump head.

▪

It is recommended to replace the diaphragm when the

head parts are removed.

Qty.

Tool

1

Screwdriver TORX T6

Tab. 15

Information on procedure

Prior requirements

Tools