Page 9 of 13

Maintenance

1. Before dismantling the unit, exhaust the air in the line completely.

2. Dismantle the components and clean them in kerosene and blow with compressed air.

3. Check for damages in the O-rings (15), (16.1), (17) and at sealing areas in the valve cone

rubber, spherical relieving seating, seating area of the housing, etc. Replace if needed or

clean and reassemble.

4. For assembly of the unit: Apply general purpose grease on the O-rings (15), (16.1), (17) and

on the cylindrical surface of the valve cone (13), on threads of the adjusting screw (7), and on

bearing washer (6). Reassemble all the components.

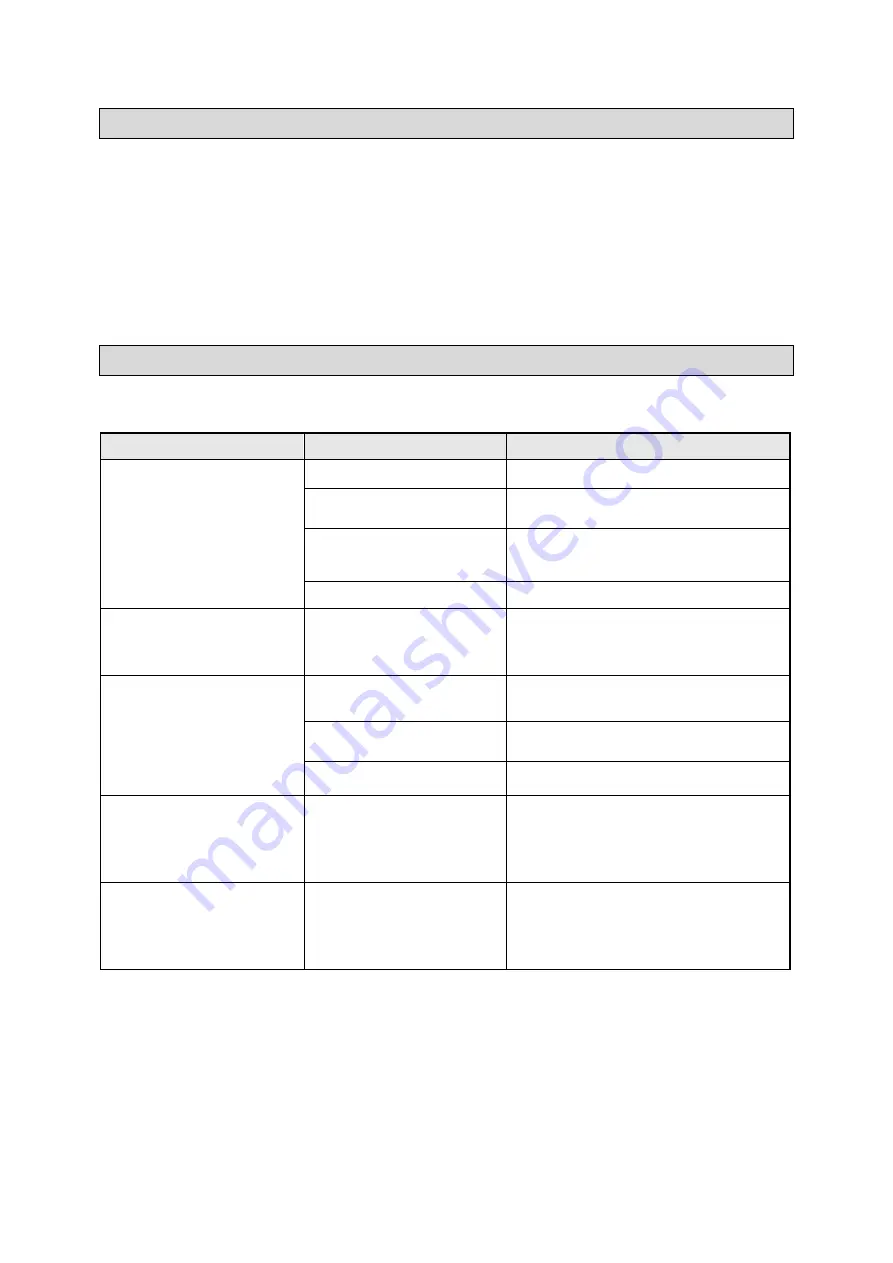

Troubleshooting

Use the table below to troubleshoot problems before contacting service personnel or your local

dealer. If the problem continues after troubleshooting, call your local dealer for assistance.

Failure

Possible Cause

Corrective Action

Continuous leak through the

knob (1).

Diaphragm (9) damaged.

Replace Diaphragm assembly (9).

Relieving spherical seating

of the valve cone damaged.

Replace valve cone assembly (13).

Dirt found in between the

seating and the valve cone

(13).

Clean and reassemble.

O-ring (16.1) damaged.

Replace the o-ring (16.1).

Air leaks through housing

and bottom plug (16)

interface.

O-ring (15) damaged.

Replace the o-ring (15).

Setting pressure goes on

increasing slowly.

Relieving spherical seat of

the valve cone damaged.

Replace the valve cone assembly (13).

Dirt found in between the

seating and the valve cone.

Clean and reassemble.

O-ring (16.1) damaged.

Replace the o-ring (16.1).

After frequent use of

adjustment knob, the

pressure setting

becomes

impossible.

Wearing out of the adjusting

Screw (7).

Replace the adjusting screw assembly

and apply general purpose grease on

threads and at washer (6).

Supply pressure directly

connected to outlet

port and making

pressure setting

impossible.

Valve cone assembly (13)

is stuck.

Dismantle the valve assembly (13).

Clean using kerosene and air jet.

Reassemble after applying general

purpose grease on o-ring (17) and on

the valve cone cylindrical portion.

Содержание 57392

Страница 10: ...Page 10 of 13 Parts Diagram...