150'

14 AWG

12 AWG

12 AWG

Nameplate AMPS

25'

18 AWG

18 AWG

16 AWG

14 AWG

50'

16 AWG

16 AWG

16 AWG

12 AWG

100'

16 AWG

14 AWG

14 AWG

Minimum Wire Size Of Extension Cords

0-6

6-10

10-12

12-16

Cord Length

NOT RECOMMENDED

6 of 34

7 of 34

Milling and Drilling Machine

OWNER’S MANUAL

Extension Cords

WARNING:

• USE A PROPER EXTENSION CORD. Make sure your extension cord is in good condition.

When using an extension cord, be sure to use one heavy enough to carry the current your

product will draw. An undersized cord will cause a drop in line voltage, resulting in loss of

power and cause overheating.

• Be sure your extension cord is properly wired and in good condition. Always replace a

damaged extension cord or have it repaired by a qualified person before using it. Protect

your extension cords from sharp objects, excessive heat and damp or wet areas.

• Grounded tools require a 3-wire extension cord. Double Insulated tools can use either a 2- or

3-wire extension cord.

• As the distance from the supply outlet increases, you must use a heavier gauge extension

cord. Using extension cords with inadequately sized wire causes a serious drop in voltage,

resulting in loss of power and possible tool damage.

• The smaller the gauge number of the wire, the greater the capacity of the cord. For example,

a 14-gauge cord can carry a higher current than a 16-gauge cord. Minimum extension cord

wire size is shown in the following table:

• When using more than one extension cord to make up the total length, make sure each cord

contains at least the minimum wire size required.

• If you are using one extension cord for more than one tool, add the nameplate amperes and

use the sum to determine the required minimum cord size.

• If you are using an extension cord outdoors, make sure it is marked with the suffix W-A (W in

Canada) to indicate it is acceptable for outdoor use.

• Make sure your extension cord is properly wired and in good electrical condition. Always

replace a damaged extension cord or have it repaired by a qualified electrician before using

it.

• Protect your extension cords from sharp objects, excessive heat, and damp or wet areas.

Unpacking Instructions

This machine has been inspected and tested before delivery. Once it is properly installed it can

be operated immediately. The machine is covered with water-proof and oil-resisting cloth, fixed

tightly on a pallet and packed in wooden crate. In the crate, there is also a box of accessories.

The steel fastening straps around the crate are under tension. Cut off the straps with shears.

When removing the straps, the workers should wear eye-protecting glasses and gloves. Please

take care since the sheared edges are very sharp. After taking off the straps, remove the nails

and unpack the wooden crate.

Milling and Drilling Machine

OWNER’S MANUAL

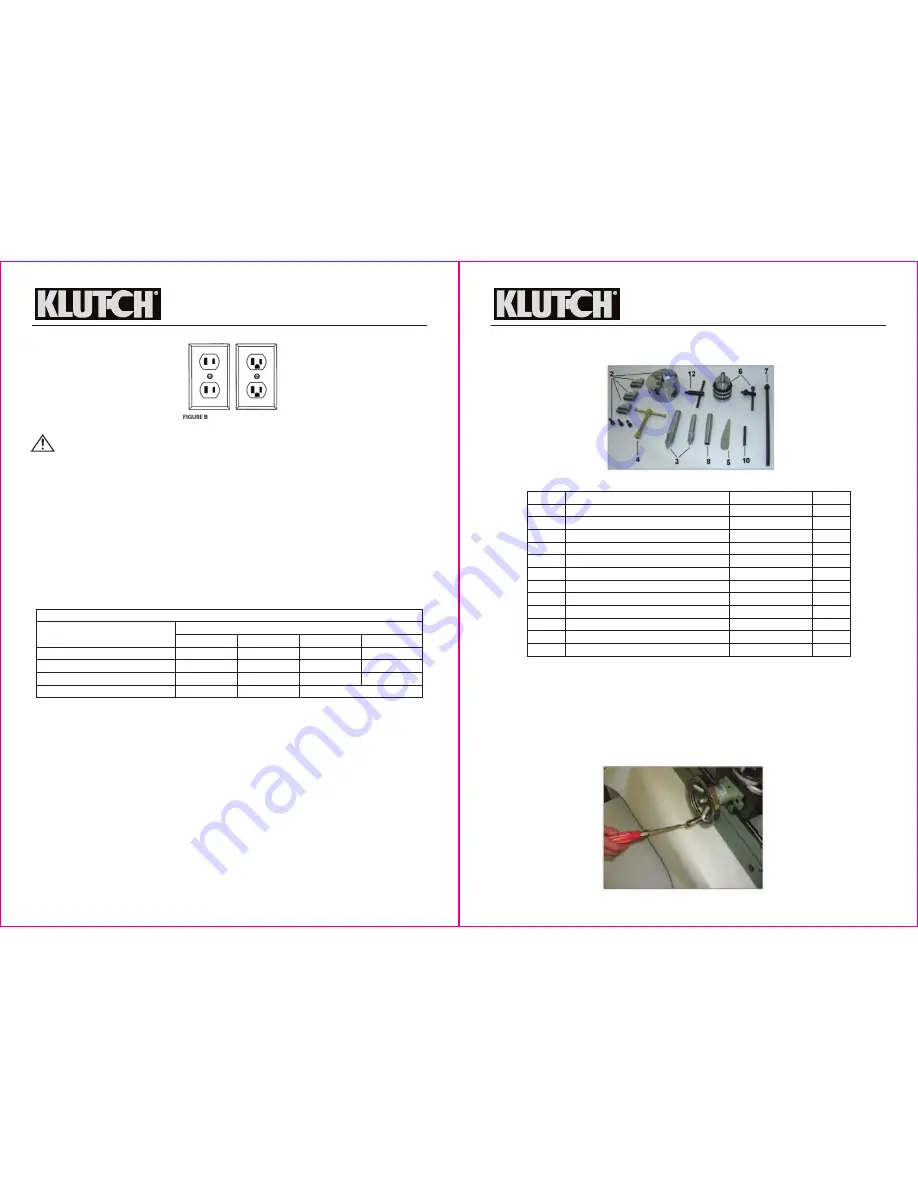

Open the box of accessories and check the accessories according to the photo shown below

(Fig.1). Check them with the Packing List.

When installing the machine, the user should provide a solid pedestal to support the machine.

The pedestal should be level and well adjusted. The installation location should allow enough

area for operating. On the left of the machine, there should be enough area for turning rod

material.

On the surface of the machine, there is a protective layer of oil which can be cleaned with

noncorrosive kerosene or petroleum solvent. After installation and cleaning, the machine should

be lubricated (see Operating Instruction/Lubrication).

For shipping reasons, the feeding handle of the Transverse Wheel (9) was installed inwards.

Before operation, it should be reinstalled outwards as shown in Fig. 2.

No.

1

2

3

4

5

6

7

8

9

10

11

12

Description

Milling/Drilling Machine

Spindle chuck, jaws (3), set screws (3)

Dead Centers

Pressing Cutter Wrench

Wedge

Drilling Chuck & Key

Draw Bar

Drill Taper Shank

Flange (on machine)

Locking Lever

Owner’s Manual (this manual)

Chuck Key

Specification

L-H007

Ø100

Morse No. 2 & 3

JS16

MT #2

Qty.

1

1

1 each

1

1

1

1

1

1

1

1

1

Fig. 1: Accessories

Fig. 2