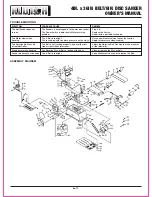

4IN. x 36IN. BELT/6IN. DISC SANDER

OWNER’S MANUAL

4 of 7

• Whenever adjusting or replacing any parts on the tool, turn

switch OFF and remove the plug from power source.

• Recheck table handle and bolts. They must be tightened

securely.

• Make sure all guards are properly attached. All guards s

hould be securely fastened.

• Make sure all moving parts are free and clear of any interfere

nce.

• Make sure all fasteners are tight and have not vibrated loose.

• With power disconnected, test operation by hand for clear

ance and adjust if necessary.

• Always wear eye protection or face shield.

• Make sure abrasive belt always tracks properly. Correct

tracking gives optimum performance.

• After turning switch on, always allow belt and disc to come

up to full speed before sanding or grinding.

• Be sure disc turns counterclockwise. Abrasive belt must

travel downward.

• Avoid kickback by sanding in accordance with the directional

arrows.

• Keep your hands clear of abrasive belt, disc and all moving

parts.

• For optimum performance, do not stall motor or reduce

speed. Do not force the workpiece into the abrasive surface.

• Always support workpiece with table or back stop when

sanding with belt and with table when sanding with disc.

• Never push a sharp corner of the workpiece rapidly against

the belt or disc. Abrasive backing may tear.

• Replace abrasives when they become loaded (glazed) or

frayed.

LEVELING THE TABLE ASSEMBLY

• Place a combination square on the Table so that it touches

the Abrasive Disc. If the Table is 90 degrees to the Sanding

Paper, the square should be flush on the Pad.

• If the Table is not 90 degrees, loosen the locking handle and

tilt the Table until the square is flush with the Pad.

• Tighten the Knob to secure the Table.

• Loosen the Angle Pointer Screw and adjust it so that it points

to 90 degrees.

A

DJUSTING THE ABRASIVE BELT TRACKING

• Turn the Belt Sander on, if the Belt slides off either Roller, the

Belt Tracking needs to be adjusted to center on idler drums.

• If belt moves to the left, turn tracking nut to the right. If belt

moves to the right, turn tracking nut to the left.

• Turn the Belt Sander on again, if the Belt still slides off to one

side, continue adjusting tracking nut as needed to center belt

on drums.

ADJUSTING THE ABRASIVE BELT POSITION

CAUTION: Never make adjustments to the Belt Sander

without unplugging the plug from the electrical outlet.

• Loosen the Socket Head Bolt that is threaded into the Pivot

Bracket.

• Tilt the Belt Assembly to desired position. Secure the Belt

Assembly by tightening the Socket Head Bolt in to the Pivot

Bracket.

• Adjustable Positive Stops are provided for both horizontal

and vertical positions.

NOTE:

The horizontal limit stop is located on top of the base

and the vertical limit stop is located beneath belt cover.

ADJUSTING TABLE ANGLE

Table is used to support workpiece when sanding on the disc

or on the belt,

when the belt assembly is in the vertical position.

To adjust table angle, loosen handle (#26), tilt table to desired

position, then secure by tightening handle.

HORIZONTAL BELT SANDING WITH BACK STOP

Back stop supports the workpiece when sanding on the belt

with the belt assembly in the horizontal position.

• Remove table and stud from belt assembly.

• Tilt belt assembly from vertical to horizontal position and

secure in position.

• Mount back stop to belt assembly using the two bolts.

• Idler drum can be used as a contact drum to sand surfaces.

ABRASIVE BELT SANDING

• Finishing flat surfaces: Hold workpiece firmly with both

hands; keep fingers away from abrasive belt. Use table to

position and secure work being sanded. Keep end butted

against table and move work evenly across abrasive belt.

• Finishing long pieces: Use belt in horizontal position with

back stop. Apply only enough pressure to allow abrasive belt

to remove material. Use back stop to position and secure