IOM-KHD-21E(a)-110_V1.1_EN

Copyright

©

2022 by KLINGER DIE ERSTE INDUSTRY CO., LTD.

5

4

IOM-KHD-21E(a)-110_V1.1_EN

Copyright

©

2022 by KLINGER DIE ERSTE INDUSTRY CO., LTD.

Standard 2-Piece Ball Valve

KHD-21E(a)

Standard 2-Piece Ball Valve

KHD-21E(a)

Chapter II

Installation

Flush the pipeline carefully before installing the

valve. The particles of dirt or debris or welding may

damage the ball sealing surface and seats. Also, be-

fore installing, check all valve and pipe connection to

ensure threads are free from defects.

2.1 General Notes

1) Direction

Series 21E(a) Standard 2-Piece ball valves are bi-di-

rectionally sealed unless otherwise specified.

Note:

If requested, valves with upstream hole in ball are

one-way valves.

2) Position

The body, cap and gasket are in the connection area

of ball valve and pipeline. The bear weight ability

and gradient are very important to the pipe instal-

lation. Do not make the pressure from the pipeline,

and stress to concentrate on the connecting area of

body and cap. Ball, seat, and stem will be damaged.

Consequently, deformation and leakage may occur.

Note:

Most of the valves do not restrict the flow

direction when installing the Series 21E(a) Ball

Valve. However, KLINGER DIE ERSTE suggests ver-

tical or horizontal position to maximize sealing and

reduce the accumulation. In the case of vertical

installation, upstream pressure should be locat-

ed above, since in the floating ball design, the ball

helps the sealing effects.

3) Fittings

Select the correct size of fittings according to the

pipeline specification. Mating the valve to the pipe-

line adequately with appropriate bolts. Do not at-

tempt to correct pipeline misalignment by means of

flanged bolting.

Note:

Over tightening of any side may cause leakage.

4) Systems hydrostatic test

Before delivery, valves are tested 1.5 times the al-

lowable pressure at ambient temperature in OPEN

position. However, after installation, the piping sys-

tem may subject to system tests, as condition not

to exceed the marking pressure.

5) Pre-Installation Wash

Before the valve installation, clean the pipeline sys-

tem to remove any foreign deposits by water. Clean

the connecting flanged end surfaces as well to en-

sure tight sealing.

2.2 Installation of Ends

Threaded Ends

It is not necessary to disassemble threaded end

valves before installation. Note that the taper

threaded fitting should not be over tightened.

CAUTION:

Do not exceed the valve performance limitation.

CAUTION:

Before installing, make sure the line pressure has

been relieved, and any hazardous fluids have been

drained or purged from the system.

used in the pipeline system, unless otherwise spec-

ified with the category III in Declaration of conformi-

ty.

These valves, when installed, have body connec-

tors which form an integral part of the pipeline

and the valve cannot be removed from the pipeline

without being dismantled.

1.4 Storage

If the valves are not to be installed immediately,

please store the valve carefully before installation,

preferably indoors in a dry and clean place.

Also, the valve ports should be sealed by plastic

caps to prevent dirt from entering and damaging in-

ner parts.

Chapter III

Operation

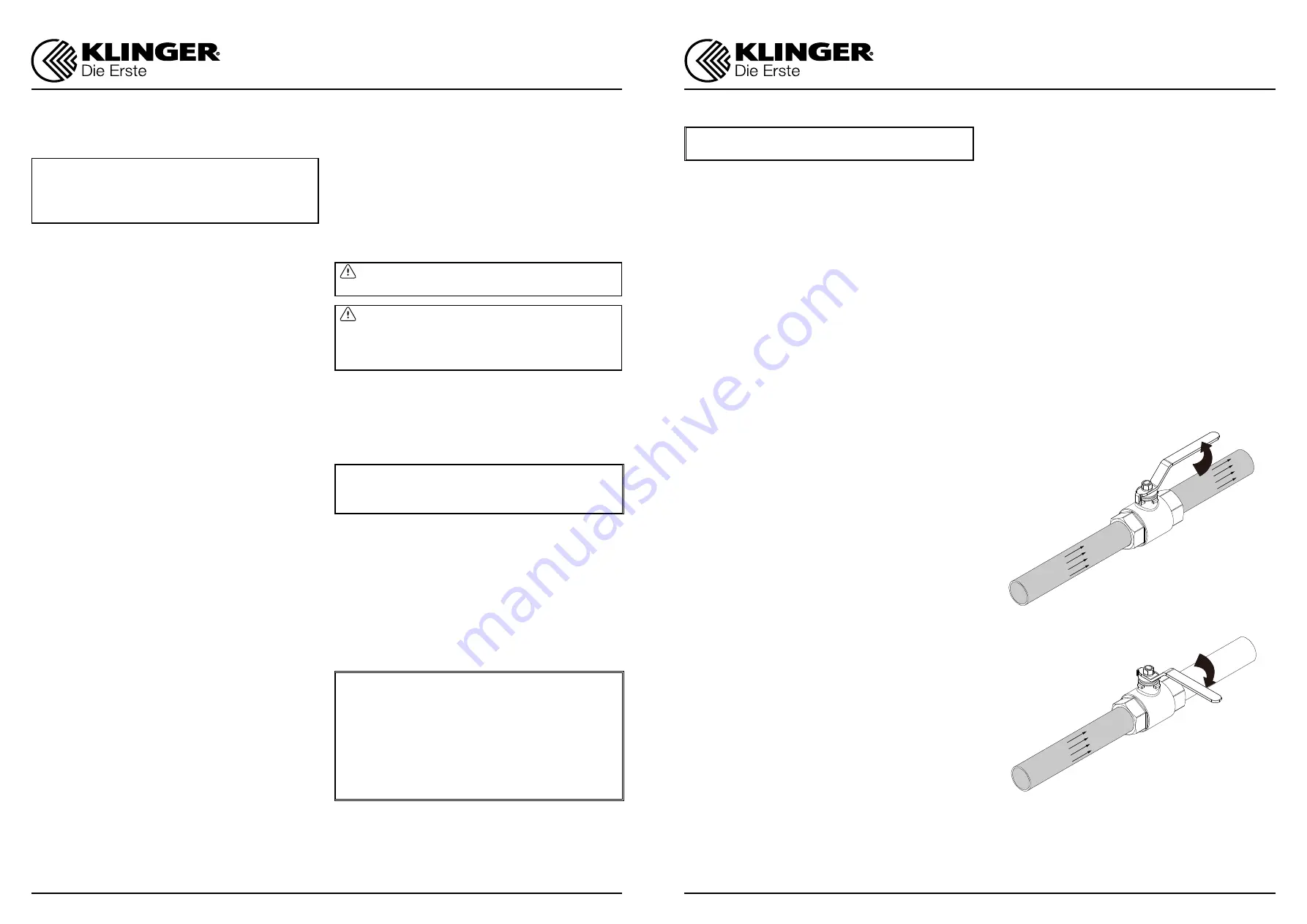

For manual operation, shift the handle in clockwise

direction for CLOSED and counter-clockwise for

OPEN.

If the handle is in parallel position with the flow di-

rection, the valve is OPEN. If the handle is in right

angle position with the flow direction, the valve is

CLOSED.

When installing actuator or the valve is operated

with removable handle, the user should ensure the

position of the valve whether open or close. The

Double-D orientation indicates whether the valve is

in OPEN or in CLOSED position. The below Figure 3.1

provides the visual understanding of above expla-

nation.

Figure 3.1 Rotation Direction for

CLOSED and OPEN position

CLOSE

OPEN