Klimawent

– the warranty of highest quality at attractive price

6 z 16

Filtering unit

BIG-2000/Ex

02.10.2019

Table No.2

– Dimensions

A

B

C

D

E

F

G

H

I

J

a

b

c

d

x

y

[mm]

[mm]

[mm] [mm]

[mm]

[mm] [mm]

[mm] [mm] [mm]

[mm] [mm] [mm]

[mm] [pieces] [pieces]

1390

960

3356 1200

1053

2550 3100

600

1320 1500

200

233

150

180

6

2

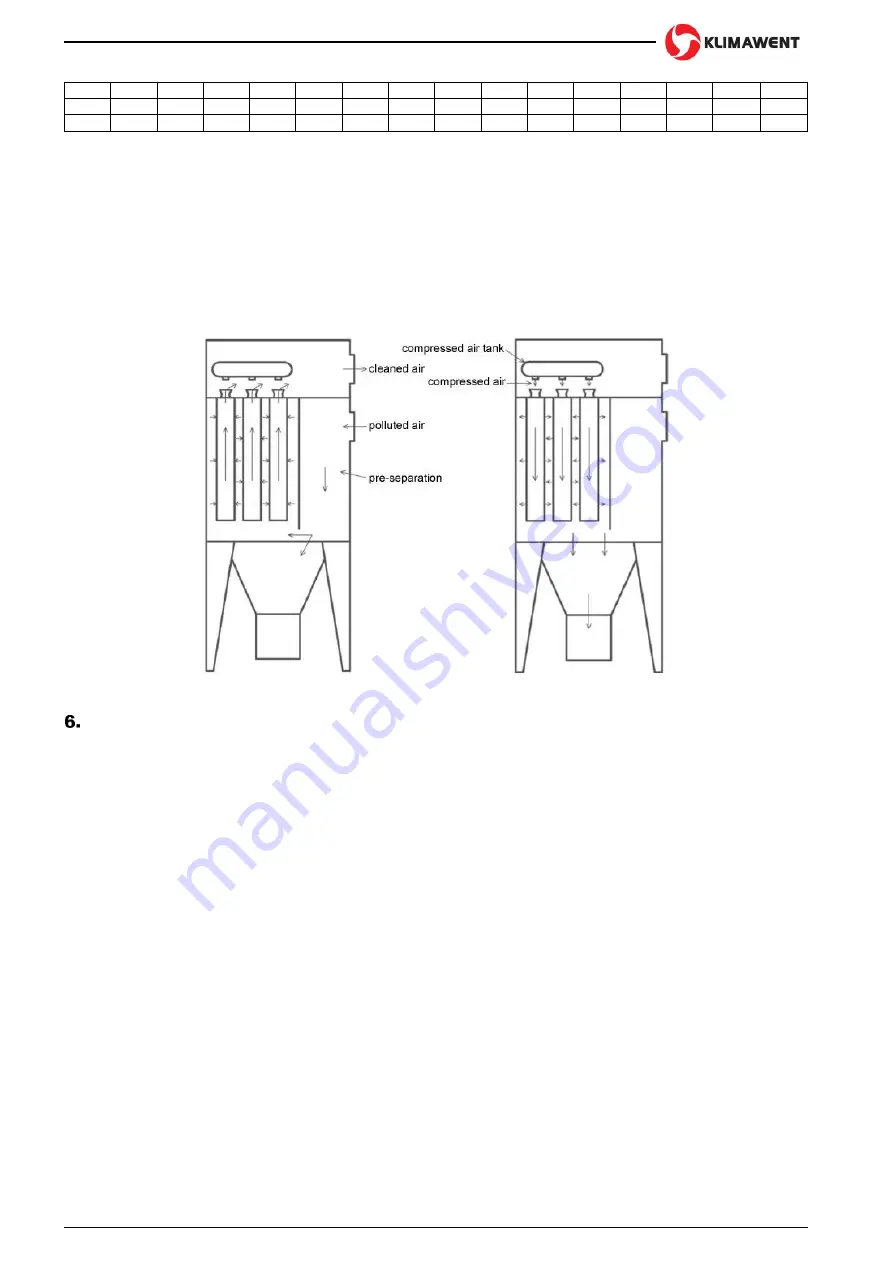

5.2 Function

BIG-2000/Ex filtering unit provides separation of the air containing dry dust fraction. The dust laden air is guided

to the chamber of filters. Here, in the decompression process and because of the flow velocity reduction, larger

particles of dust are extracted into the hopper chamber, and subsequently they fall into the waste container.

Precise dust cleaning proceeds while the air flows through the cartridge filters. In the Fig. No.5 is presented a run

diagram of the air flow through the filtering unit. As the dust accumulates on the operational surface of the cartridge

filters, this reduces the air flow intensity. To limit this disturbance, the device is equipped with a continuous

regeneration system of the filters. The impulses of compressed air (directed into the cartridge filters) strike off the

dust particles. The cleaning air is supplied from the compressed air tank, through the electromagnetic valves that

are operated by the micro-controller (in details described in Section No.7).

In the Fig. No.6 is illustrated a schematic diagram of regeneration of the cartridge filters.

Fig. No.5 Filtration scheme

Fig. No.6 Scheme of filters regeneration

ASSEMBLY AND STARTUP

6.1 Description of mounting

Before the assembly of the device in the place of use, check if the device is complete, and if it is not damaged, or

there are indentations, etc. The appliance is delivered in two assemblies, so it should be installed by means of

adequate lifting devices and by a specialised assembly team.

First, put the supporting structure with the hopper chamber. The supporting frame should be levelled and its legs

fastened firmly to the floor. Having installed the first assembly, put the chamber of filters (with the fixed to it

regeneration chamber) on it. Handle with care, as the assembly is of large dimensions. At the upper part of the

regeneration chamber are installed lifting hooks (for lifting and positioning during the transport and assembly

activities).

After the chamber of filters is connected with the supporting structure, seal up the join surface

with “silicone” and

screw it up thoroughly with bolts. The screws, bolts and “silicone” are delivered by manufacturer along with the

device.

The compressed air tank and the electromagnetic valves are delivered to the operator in completely assembled

state. Having installed the device, connect it to the external compressed air installation of 0,6

0,8 MPa. The

pressure air must not contain pollutants, oil and humidity.

The connection must be equipped with a cut-off valve, air filter and a dewaterer. These elements are not

delivered along with the device.

The nominal diameter of the compressed air connection (for the device of 2 cartridge filters and at the nominal

diameter of the compress

ed air tank of 8”) should be 1”1/2. Connection to the compressed air tank – diameter

12mm (quick-connector).

6.2 Start-up

Upon first operation of the compressed air installation (of the device), check if the connected part of the

compressed air system is sufficiently cleaned of the metal particles, rust, etc., because the membrane of the ele-

ctromagnetic valves would get damaged. If in the first stage of start-up there is not enough air flow intensity (in

the system)

– this means the valves are not tight enough. Shut the cut-off valve in the supply of the compressed

air tank. Wait until the air pressure in the system reaches 0,6

0,8 MPa, and then quickly open the cut-off valve.