14

| Circular fire damper user manual 03/2020

15

|

Circular fi

re damper user manual 03/2020

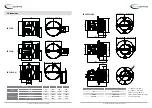

5.2.11 Installation in gypsum blocks wall 70mm

The wall is composed of gypsum blocks (minimum density of 995kg/m

³), and with minimum thickness

of 70mm.

30

30

30

45º

30

150

150

Prepare opening in the wall

according to dimension table (on

page 6)

Insert fire damper into wall

Fire damper can be installed with

minimal distance of 30 mm between

wall, ceiling or other dampers.

Cover the mortar with GKF gypsum

boards (12,5 mm thick)

Space between casing and wall

close with mortar

5.2.9 Installation in ceiling (Weichschott)

The ceiling is composed of aerated concrete blocks (minimum density of 550 kg/m

³) and with a

minimum thickness of 100 mm.

Recommended ceiling opening

for fire damper installation is

Ø+ 400mm, but openings from

Ø + 80…600 mm can also be used

Insert fire damper into ceiling

Damper blade must be closed

during installation!

Space between casing and wall

close with two layers of mineral

wool (density 140 kg/m³ or more, 50

mm thick, coated on one side)

Connections of mineral wool should be

sealed with intumescent fire resistant sealant

(e.g. Promastop-I or Hilti CFS-CT). Mineral

wool and damper casing must be coated with

2 mm thick fire protection coating

5.2.10 Suspension for mortarless installation

Suspension systems are required for the dry mortarless installation of the fire damper with mineral

wool in solid walls, flexible walls and ceiling slabs. Fire dampers can be suspended from solid ceiling

slabs using adequately sized threaded rods. Load the suspension system only with the weight of the

fire damper. Ducts must be suspended separately.

1

3

2

1

4

5

Dn + 70

Dn + 70

Wall installation

Ceiling installation

Threaded rod (M10),

galvanized steel

Washer, galvanized steel

Nut, galvanized steel

Bracket, 45x30x1,5 mm,

galvanized steel

L shaped profile (50x50x1)

secured with self tapping

screw to damper housing

1

2

3

4

5