24

| Circular fire damper user manual 03/2020

25

|

Circular fi

re damper user manual 03/2020

8. Other mechanism

BELIMO

Operation

Damper is delivered in closed position. When

electric actuator is connected to the power

supply damper will open. When the damper

reaches the end position (damper open), the

electromotor will stop. Closing fire damper

takes place automatically when a power failure

occurs. Thermal tripping device that comes

with fire damper causes power circuit break at

a temperature of 72 °C (inside or outside duct).

If checking is needed for proper functioning of

fire damper, pushing the switch on the thermal

tripping device will close damper. When switch

on tripping device is released, the damper will

open.

Damper can be opened without connecting

to a voltage with enclosed handle turning in

the direction of the arrow on electric actuator

(clockwise). Damper can be locked in the desired

position by fast turning back handle a quarter of

a turn (counterclockwise) for Belimo BF, and by

puling brake on Belimo BFL and BFN.

To unlock the electromotor, turn handle

clockwise for a quarter of a turn for Belimo BF,

or release brake for Belimo BFL and BFN. After

release, damper will be closed by return spring.

When damper is opened manually, electric

actuator will not move the damper into closed

position after power failure.

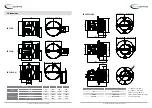

Wiring diagram

1

negative (direct-current) or neutral (alternating current)

2

positive (direct-current) or faze (alternating current)

S1

common micro switch closed damper

S2

normally closed micro switch closed damper

S3

normally open micro switch closed damper

S4

common micro switch open damper

S5

normally closed micro switch open damper

S6

normally open micro switch open damper

Tf1

temperature sensor on the outer side of the duct (ambienttemperature) max. 72°C

Tf2

temperature sensor on the inner side of the duct (temperature in the duct) max. 72°C

Tf3

temperature sensor on the inner side of the duct (temperature in the duct) max. 72°C

Type of Belimo actuator

BFL24-T

BFN24-T

BFL230-T

BFN230-T

BF24-T

BF230-T

Nominal

voltage /

power con

-

sumption

voltage

AC/DC 24V,

50/60Hz

AC 24V,

50/60Hz

AC 230V,

50/60Hz

AC 230V,

50/60Hz

AC/DC 24V,

50/60Hz

AC 230V,

50/60Hz

opening

2,5 W

4 W

3,5 W

5 W

7 W

8.5 W

holding

0,8 W

1,4 W

1,1 W

2,1 W

2 W

3 W

for wire sizing

4 VA

6 VA

6,5 VA

10 VA

10 VA

11 VA

End switch

1 mA...3

A (0,5 A),

DC 5 V...AC

250V

1 mA...3

A (0.5 A),

DC 5 V...AC

250 V

1 mA...3

A (0.5 A),

DC 5 V...AC

250 V

1 mA...3

A (0.5 A),

DC 5 V...AC

250 V

1 mA...6 A

(3 A), DC

5 V...AC

250 V

1 mA...3

A (0.5 A),

DC 5 V...AC

250 V

Running

time

motor

<60 s

<60 s

<60 s

<60 s

<120 s

<120 s

spring-return

~20 s

~20 s

~20 s

~20 s

~16 s

~16 s

Ambient temperature range

min. -30°C, max. 50°C

SCHISCHEK ExMax

Operation

Damper is delivered in closed position. When

electricactuator is connected to the power supply

damperwill open. When the damper reaches

the end position(damper open), in which is it

blocked, the electromotorwill stop. Closing fire

damper takes place automatically when a power

failure occurs. Thermal tripping device that

comes with fire damper causes power circuit

break at a temperature of 72 °C (inside or outside

duct). If checking is needed for proper unctioning

of fire damper, pushing the switch on the thermal

tripping device will close damper. When switch on

tripping device is released, the damper will open.

Damper can be opened without connecting to a

voltage with enclosed Allen key, by turning in the

direction of the arrow on electric actuator

(clockwise). After release of Allen key, damper

will go to closed position.

Type Examination Certificate Number: EXA 14

ATEX0064X

Equippment complies with the essential health

and safety requirements relating to the design

and construction of equippment intended to use

in potentially explosive atmospheres given in

annex II of the directive 94/9/EC..

Wiring diagram