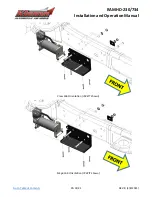

RAMHD-230/734

Installation and Operation Manual

PG 40/41

REV: B (4/8/2021)

13.

Routine Maintenance

Perform following steps at least once during recommended intervals.

1.

Yearly, or every 12000 miles verify all mounting fasteners are properly torqued; applying witness marks

across fasteners and mounting parts is good practice to quickly ensure fasteners have not moved.

2.

Yearly, or every 12000 miles remove all road grime and mud from mounting brackets and kit parts using

clean water from a garden hose; pay special attention to corners where dirt may collect. Touch up all

paint chips using automotive grade enamel in either spray, or brush form.

NOTE high pressure washers may damage part finishes and must be used with care. Do this more

frequently if traveling regularly off-road, or in winter climates where road salts are used.

3.

Yearly, or every 12000 miles check electrical and air fitting connections and wires for abrasion,

corrosion, or other damage. Replace damaged components.

NOTE: if system runs continuously or turns on unexpectedly, leaks or intermittent electrical connection

may be present.

4.

Monthly, or every 10 hours of compressor run time, drain moisture from air tank using drain valve

installed at bottom of tank.

WARNING:

Failure to regularly drain air tank may result in corrosion inside tank and possible failure in

tank or air lines, which can suddenly release air pressure causing injury to nearby people.

5.

Yearly, or every 12000 miles clean, or replace air compressor air filter element. Replacement frequency

depends on operating frequency and conditions of operating environment (i.e., daily use of air

compressor in dusty, or wet environment requires more frequent filter change). Order replacement

filters at

NOTE: Never lubricate or add any liquids to the included oil-less air compressor.