26

NOTE:

We strongly recommend jacking the product up when

performing inspection and work on the cutting device. Avoid

tilting the product in order to prevent fuel and oil leakages.

1. Keep the underbody and cutting device (23) clean and free of debris. Remove clippings from the discharge chute (24).

2. Check all nuts and bolts periodically for tightness before operation. After prolonged use, especially in sandy soil conditions, the

cutting device will become worn and lose device should be replaced.

3. Keep the cutting device (23) sharp to ensure a good cutting performance. Replace a worn or damaged cutting device with a new

one of the same type or have it sharpened

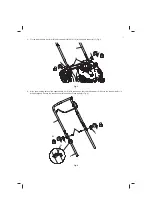

4. Loosen the hex bolt (23e) anti-clockwise using a suitable wrench and remove it together with the locking

À

ange (23d), cutting

device (23), support (23c), and pin (23b) (Fig. 20).

23a

23b

23c

23

23d

23e

Fig. 20

5. Replace the cutting device with a new one of the same type. Slide the pin (23b) into the slot on the spindle (23a) (23c), support

(23d), locking

À

ange (23e) and hex bolt (23f). Tighten the hex bolt clockwise with 40 N m min, 50 N m max. to ensure safe

operation of your product.

NOTE:

Replace this cutting device after 50 hours mowing or

2 years whichever is sooner regardless of condition. If the

cutting device is cracked or damaged, you must immediately

replace it with a new one.

6. Lubricate the cutting device (23) after each use to prolong the life span of cutting device and product. Apply light machine oil

along the edge of the cutting device.

Grass catcher

1. Inspect the grass catcher (20) before each use. Do not use it if you

¿

nd any damage.

2. Clean the grass catcher (20) after operation using water and mild soap.

3. Let the grass catcher dry thoroughly before storing to avoid mildew.

Wires

Check the performance of the wires (4) before each use. Ask a quali

¿

ed specialist to adjust it if necessary.