assembly & adJustments

moving your bandsaw

1. Use a 2000kg. chain hoist connected to the top mounted transport hook to

move the bandsaw to the desired location.

2. To ensure sufficient stability and security, bolt the base of the bandsaw to the

floor using the 4 mounting holes.

assembly

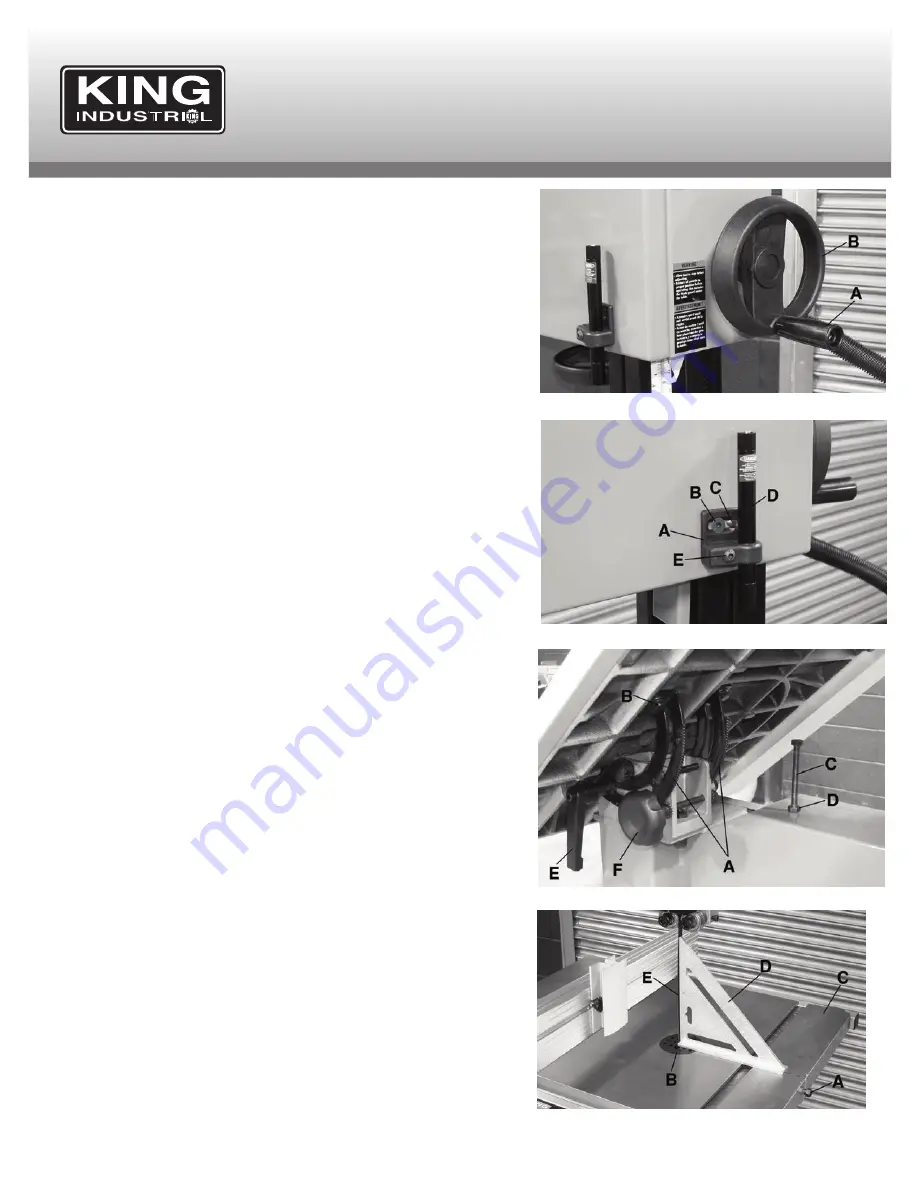

mounting top Handwheel and laser guide

1. Attach handle (A) Fig. 1 to the handwheel (B), then slide the handwheel onto

the shaft on the side of the bandsaw. Secure the handwheel by tightening the

cap screw with a hex. key (located on the hub of the handwheel).

2. Install the laser guide mounting bracket (A) Fig.2 to the upper wheel cover by

threading the countersunk head screw (B) from the outside and the pan head

screw (C) from the inside of the wheel cover.

3. Install batteries (2 x AA batteries) inside the laser guide (D), then slide it into

the mounting bracket (A) and secure it by tightening the fixing screw (E).

mounting and adjusting table

1. To mount the table (C) Fig.4, remove table insert (A) Fig.4 and table pin (B)

Fig.4 from the table.

2. Slide the blade through the table and place the table onto the trunnions (A)

Fig.3, line up the 4 mounting holes and fix table to the trunnions using spring

washers and hex. bolts (B) Fig.3, then replace table insert and table pin.

3. Loosen lock handle (E) Fig.3 and turn the micro-adjustment knob (F) Fig.3 to

tilt the table (as shown in Fig.3), retighten lock handle. Install the 90

0

stop bolt

and nut (C & D) Fig.3 to the main frame. Lower the table until it rests against

the 90

0

stop bolt.

4. Place a square (D) Fig.4 on the table and up against the blade (E) Fig.4 to

see if the table is 90

0

to the blade. If the table is not 90

0

, an adjustment to the

90

0

stop bolt and nut (C & D) Fig.3 is needed.

5. Loosen lock handle (E) Fig.3 and turn the micro-adjustment knob (F) to posi-

tion table at 90

0

. Loosen hex. nut (D) Fig.3 and adjust the height of the 90

0

stop bolt (C) Fig.3 as needed. After the adjustment, retighten the hex. nut (D)

Fig.3 and re-adjust the position the angle pointer (under the trunnion) to 0

0

.

Figure 1

Figure 2

Figure 3

Figure 4

Содержание KC-1700WM-VS

Страница 11: ...ELECTRICAL DIAGRAM model kc 1700wm vs...