MAINTENANCE

INSPECTING/REPLACING CARbON bRUSHES

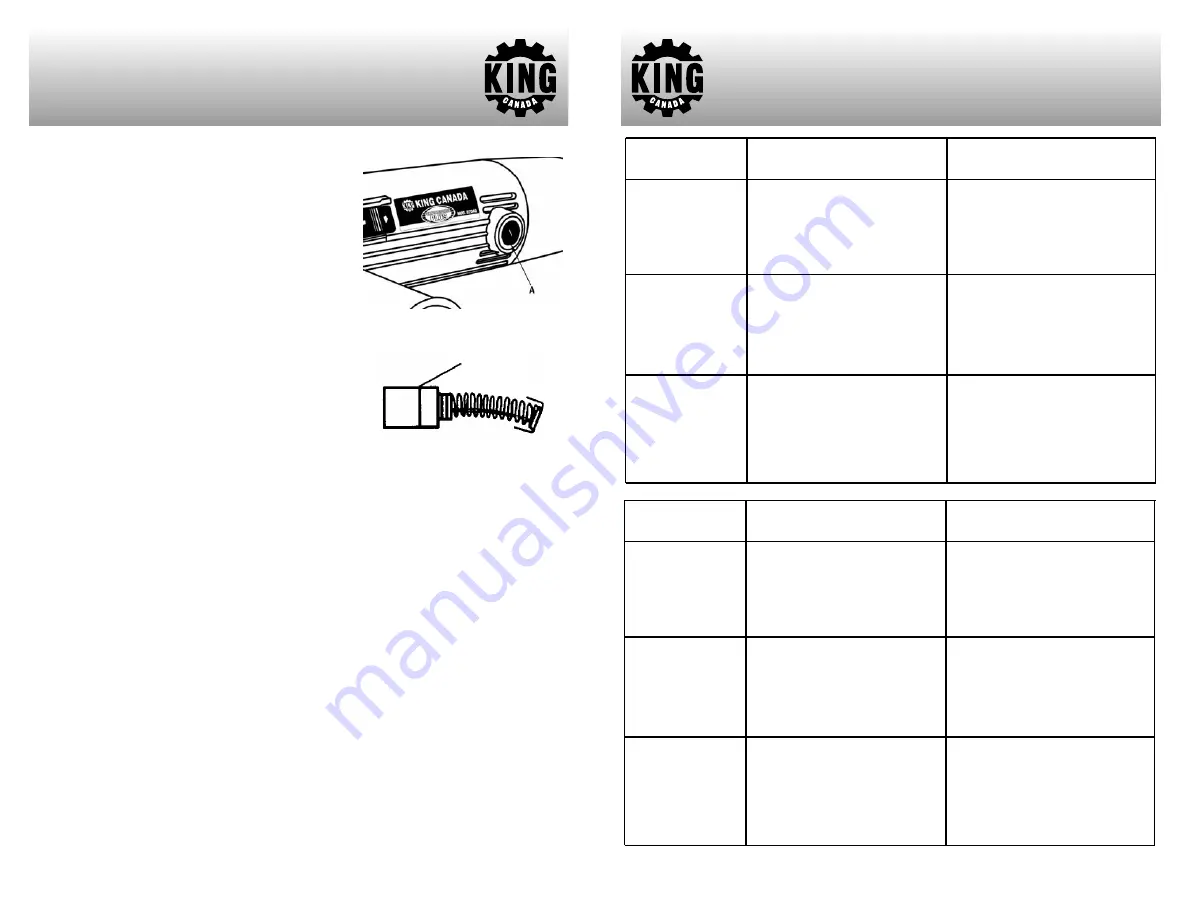

Remove and check the carbon brushes regularly

(normally after 50 hours of use). The carbon brushes

are installed inside the motor housing. Using a

screwdriver, remove the carbon brush caps (A) Fig.7

on both sides of the motor housing.

Remove the carbon brush (A) Fig.8 from the motor

housing and inspect it. Repeat this step for the

second carbon brush. Carbon brushes need to be

replaced once they wear down to the small limit mark

as shown in Fig.8. Keep the carbon brushes clean

and free to slip in the holders.

If they have worn down to the limit mark, purchase a

set of identical replacement carbon brushes (both

carbon brushes should be replaced at the same

time). Install new carbon brushes and reinstall the

carbon brush caps.

If you are unsure about these instructions, we

recommend that you get a qualified service technician to replace the carbon brushes.

Contact a King Canada service centre.

FREqUENT INSPECTION AND MAINTENANCE

The tool should be inspected and maintained frequently. Check and make sure the power

cord, internal wires, plug and switch are in good condition. Make sure the insulation

resistance is within normal limits, contact between the brushes and the commutator are

good, and that there is no short-circuit or breakage of the armature and stator windings.

Check the grinding wheel, bearings and driving parts also.

grease the tool frequently. grease can be volatilized and therefore the grease in the gear-

box should be kept clean, replenish or renew as needed.

Do not allow brake fluid, gasoline, petroleum-based products such as penetrating oils to

come in contact with plastic parts. They contain chemicals which can damage, weaken or

destroy the motor housing, thus compromising the intergrity of the double insulation.

Inspect mounting screws regularly, making sure they are properly tightened. Tighten all

loose screws before operating.

Service should be done by a qualified service technician using identical replacement parts.

Figure 8

Figure 7

Limit mark

TROUBLESHOOTINg

Faults

Causes

Solution

1. Motor fails to

run.

2. Motor gives

out an abnormal

sound, will not

start or runs

slowly.

3. Head

enclosure gets

too hot.

1. Power supply broke off or

connections loosened.

2. Switch contact is not good.

3. Windings of armature or

stator burnt out.

4. Stator short-circuited.

1. Switch contactors burnt out.

2. Mechanical obstruction.

3. Too much pressure on tool,

motor is overloading.

4. Armature slightly short-

circuited or opencircuited.

1. Lack of grease in head

enclosure or the grease is

contaminated by dirt.

2. Mashing of the gears too

tight or entrance of foreign

matters.

1. Reconnect or change

connections.

2. Repair or replace switch.

3. Replace the windings.

4. Weld broken leadout or

rewind the winding.

1. Repair or replace the switch.

2. Inspect the mechanical parts.

3. Reduce pressure on tool.

4. Replace or repair the

armature.

1. Add or change grease.

2. Inspect gears or clean off

foreign matters.

Faults

Causes

Solution

4. Motor runs,

but is not turning.

5. Casing gets

too hot.

6. Heavy spark-

ing occurs on the

commutator.

1. gear shaft or woodruff key

is broken.

2. Nut at small bevel gear is

not tightened.

1. Working load is too heavy.

2. Winding got wet.

3. Not properly assembled.

4. Regulated voltage drop.

1. Armature short-circuited or

opencircuited.

2. Surface of commutator is

not clean.

1. Inspect if the gear shaft or

the woodruff key is broken.

2. Tighten the nut.

1. Reduce pressure on the tool.

2. Dry the motor.

3. Inspect if the armature is

blocked or touches the stator

core.

4. Regulate supply voltage.

1. Repair the armature.

2. Clean off foreign matters

and make the surface of the

commutator is clean and

smooth.