e300i User Manual

Document #: 0503M01A

REV : 1.3

Approval:

Date: March ’08

Page 3 of 25

1

1

S

S

a

a

f

f

e

e

t

t

y

y

C

C

o

o

n

n

s

s

i

i

d

d

e

e

r

r

a

a

t

t

i

i

o

o

n

n

s

s

1

1

.

.

1

1

M

M

e

e

c

c

h

h

a

a

n

n

i

i

c

c

a

a

l

l

S

S

a

a

f

f

e

e

t

t

y

y

1

1

.

.

2

2

E

E

l

l

e

e

c

c

t

t

r

r

i

i

c

c

a

a

l

l

S

S

a

a

f

f

e

e

t

t

y

y

1

1

.

.

3

3

I

I

n

n

s

s

t

t

a

a

l

l

l

l

a

a

t

t

i

i

o

o

n

n

H

H

a

a

z

z

a

a

r

r

d

d

s

s

1

1

.

.

4

4

O

O

p

p

e

e

r

r

a

a

t

t

i

i

o

o

n

n

a

a

l

l

S

S

a

a

f

f

e

e

t

t

y

y

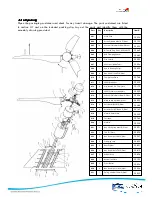

Disclaimer

Kestrel Wind Turbines makes every effort to give accurate information in this manual and is in no way

liable for any error or omission. The user of this manual assumes full responsibility and risk.

We appeal to your common sense to read and apply the safety notes. Consult professional engineers

and take advice if you are unsure.

1 SAFETY FIRST

1 SAFETY FIRST

1 SAFETY FIRST

1 SAFETY FIRST

Although Kestrel’s wind turbines are designed with your safety in mind, accidents can easily occur

and there are always inherent dangers associated with any type of machine.

Consult installation

professionals if you lack experience or confidence.

1.1 Mechanical Safety

1.1 Mechanical Safety

1.1 Mechanical Safety

1.1 Mechanical Safety

Use good handling methods and take precautions to avoid physical injury during installation and

maintenance/repair procedures. The rotating blades of any wind turbine are a main hazard. The

e300

iiii

blades are extremely tough and will cause serious injury to the body.

Never install the e300

iiii

such that any person or animal could come into accidental contact with any part of the machine. Never

approach the machine if the blades are rotating.

1.2 Electrical Safety

1.2 Electrical Safety

1.2 Electrical Safety

1.2 Electrical Safety

The e300

iiii

output voltage can become dangerous and even lethal when running on open circuit.

Maintain a healthy respect for this wind turbine.

Always short the output wires together when the

e300

iiii

is disconnected. Do not work on the system when the turbine is running or when lightning is

possible.

Disconnecting a running e300

iiii

may cause a spark and the presence of explosive

hydrogen from battery charging is always a possibility.

Adequate ventilation must be provided for

battery installations.

The wire size used for connections must be correct for the powers supplied. The

smaller the wire diameter, the higher the wire losses and therefore the heat generated in the wire.

Use correct wire sizes throughout the installation.

The amount of energy stored in a battery is

considerable and fire can result from shorts.

Fit a suitable fuse or circuit breaker in the battery cable.

In general, respect the system and use common sense. Consult a qualified electrician if you are unsure.

1.3 Installation Hazards

1.3 Installation Hazards

1.3 Installation Hazards

1.3 Installation Hazards

All installation work should be completed at ground level wherever possible.

Be very aware of the

blades during installation. Contact with the blades will only injure you, not the blades. The

installations of poles or towers pose their own dangers. Always work carefully and have an

assistant wherever possible.

Short the generator output wires (Red and Black) throughout any

installation procedure.

Consult a civil engineer or reputable builder if you are not sure about

installing structures. Always re-check the work as you progress. Slack bolts, poor workmanship and

loose electrical connections must be avoided.

1.4 Operational Safety

1.4 Operational Safety

1.4 Operational Safety

1.4 Operational Safety

The turbine blades are dangerous.

Respect a rotating turbine.

Always shut the turbine down before

approaching. This may be achieved by shorting the generator output.

Preventative maintenance is

always the best.

Checks are best carried out in calm weather conditions. Avoid any maintenance or

inspection during windy weather.

3