FOR SERVICE TECHNICIAN’S USE ONLY

PART NO. W10035270

TECH SHEET - DO NOT DISCARD

PAGE 10

TEST #5

Moisture Sensor

NOTE:

This test is started with the machine

completely assembled.

This test is performed when an automatic

cycle stops too soon, or runs much longer

than expected.

NOTE:

Dryer will shut down automatically

after 2½ hours.

The following items are part of this system:

–

Harness/connection

–

Metal sensor strips

–

Machine control electronics

1.

Activate the diagnostic test mode and

advance past saved fault codes. See

procedure on page 1.

2.

Open the dryer door. If a continuous

beep tone is heard and an alphanumeric

number is displayed on the console as

soon as the door is opened, a short

circuit exists in the moisture sensor

system.

➔

If this doesn’t happen, go to step 3.

➔

Otherwise, go to step 4.

NOTE:

Over drying may be caused by a

short circuit in the sensor system.

3.

Locate the two metal sensor strips on the

face of the lint screen housing. Bridge

these strips with a wet cloth or finger.

➔

If a continuous beep tone is heard and

a software revision number is

displayed on the console, the sensor

passes the test. Go to step 8.

➔

If not, continue with step 4.

4.

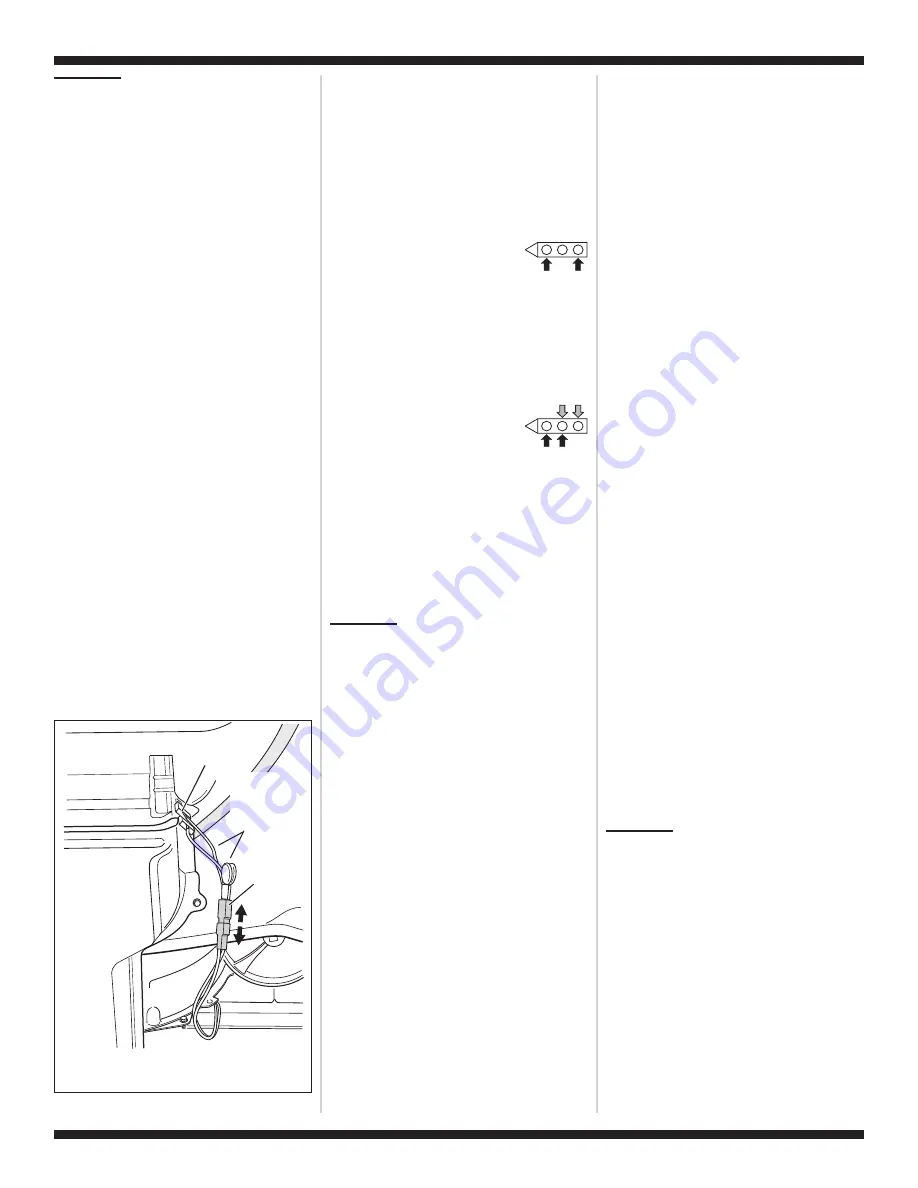

Access the moisture sensor wires by

removing the front panel. See Removing

the Front Panel/Drum Assembly, page 11.

Disconnect the sensor connector. See

figure 11.

5.

Access the machine control electronics.

See Accessing & Removing the

Electronic Assemblies, page 11. Remove

the connector P13 from the circuit board.

Check the main harness connections

between the sensor connector and

machine control for a short or open

circuit.

➔

Replace the main harness if necessary.

➔

If harness is OK, continue with step 6.

6.

Measure the resistance

across the outermost

contacts of the sensor

connector that includes the two MOVs.

➔

If a small resistance is measured,

check for debris across moisture strips

inside of the drum; clean if debris is

present. If debris is not present,

replace sensor harness with MOVs.

➔

Otherwise go to step 7.

7.

Measure the resistance across

each of the outermost

contacts and the center

terminal (ground connection).

➔

If a resistance less than infinity is

measured, replace the sensor harness

with MOVs.

8.

If moisture sensor diagnostic test passes,

check the thermistor: Perform TEST #4a,

page 9.

➔

If the problem persists after replacing

the moisture sensor, harness with

MOVs and thermistor, replace the

machine control electronics.

TEST #6

Buttons and

Indicators

This test is performed when any of the

following situations occurs during the

Console Buttons and Indicators Diagnostic

Test, page 1:

✔

None of the indicators light up

✔

No beep sound is heard

✔

Some buttons do not light indicators

None of the indicators light up:

1.

See Diagnostic Guide/Before Servicing...

on page 1.

2.

Perform TEST #1, page 6 to verify supply

connections.

3.

Perform TEST #2, page 7.

4.

Perform steps in Accessing & Removing

the Electronic Assemblies, page 11 and

visually check that the P5 connector is

inserted all the way into the machine

control electronics.

5.

Visually check the user interface

assembly connections.

6.

If both visual checks pass, replace the

user interface assembly.

7.

Plug in dryer or reconnect power.

8.

Perform the Console Buttons and

Indicators Diagnostic test, page 1 to

verify repair.

9.

If indicators still do not light, the machine

control electronics has failed:

➔

Unplug dryer or disconnect power.

➔

Replace the machine control

electronics.

➔

Plug in dryer or reconnect power.

➔

Perform the Console Buttons and

Indicators Diagnostic test, page 1 to

verify repair.

No beep sound is heard:

1.

Perform steps in Accessing & Removing

the Electronic Assemblies, page 11 and

visually check that the P5 connector is

inserted all the way into the machine

control electronics.

➔

If visual check passes, replace the user

interface assembly.

2.

Plug in dryer or reconnect power.

3.

Perform the Console Buttons and

Indicators Diagnostic test, page 1 to

verify repair.

4.

If replacing the user interface assembly

failed:

➔

Unplug dryer or disconnect power.

➔

Replace the machine control

electronics.

➔

Plug in dryer or reconnect power.

➔

Perform the Console Buttons and

Indicators Diagnostic test, page 1

to verify repair.

Some buttons do not light indicators:

1.

Perform steps in Accessing & Removing

the Electronic Assemblies, page 11 and

visually check the user interface

assembly connections.

➔

If visual check passes, replace the user

interface assembly.

2.

Plug in dryer or reconnect power.

3.

Perform the Console Buttons and

Indicators Diagnostics test, page 1 to

verify repair.

TEST #7

Door Switch

Activate the diagnostic test mode as shown

on page 1, and perform the Door Switch

Diagnostic test, page 1. Functionality is

verified with a beep each time the door is

closed and opened, and a number and letter

appears in the display (i.e.,

0E

,

09

).

If any of these conditions are not met:

➔

Unplug dryer or disconnect power.

➔

Check that the wires between the door

switch and machine control electronics

are connected. See figure 12, page 11 for

switch location and see Removing the

Front Panel/Drum Assembly, page 11.

Lint Screen

Housing

Sensor

Connector

Sensor

Sensor Harness

with MOVs

(Metal Oxide

Varistors)

Figure 11.

Disconnect sensor

connector.