Operational Check

Before installing the switch a simple operational check should be performed, as follows:

1. Fill a container with water

2. Open the electronics housing cover and connect power (see section on “

Wiring

”).

3. Set the Fail Safe jumper to the LLFS position (lower two pins).

4. Apply power

5. Place the sensor gap into the water.

a. Relay Version -- The relay will energize (the contacts between (NC) and (C) should open).

b. 2-wire Version -- The current in the Positive lead will be 20.0mA.

6. Remove the sensor from the liquid.

a. Relay Version – The relay will de-energize (the contacts between (NC) and (C) should close).

b. 2-wire Version – The current in the Positive lead will be 4.0mA.

7. Disconnect the wiring.

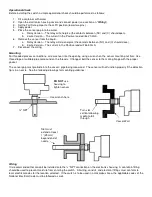

Mounting

For threaded process connections, screw sensor into the opening using a wrench on the sensor mounting nut flats. Use

thread tape or suitable pipe compound on the threads. If flanged, bolt the sensor to the mating flange with the proper

gasket.

The sensor gap must protrude into the vessel / pipe being measured. The sensor will not function properly if the detection

tip is in a nozzle. See the following drawings for mounting guidelines:

Wiring

It is recommended that conduit be installed onto the ¾” NPT connection on the electronics housing. A seal drain fitting

should be used to prevent moisture from entering the switch. All wiring, conduit, and electrical fittings must conform to

local electrical codes for the location selected. If the switch is to be used in a Hazardous Area, the applicable codes of the

National Electrical Code must be followed as well.

DO NOT

use

housing to

tighten sensor

Use wrench here

¾” NPT

Turn slot

vertical allowing

media to fall

through

Vessel Wall

Slot must

extend at least

1” (25mm)

beyond end of

nozzle