4 – KEMPPI PRO EVOLUTION PROCOOL 30 / 0532

© KEMPPI OY

A

D

H

J

I

C

F

G

2. INSTALLATION

2.2. LOCATING THE MACHINE

2.1. REMOVAL FROM PACKAGING

The equipment is packed in durable packages specially designed for them. Check the equipment

before taking it into use, to make sure that the equipment or a part of it have not got damaged

during the transportation. Also check that the delivery corresponds your order and that you have

received all the necessary instructions for installing and operating the equipment. The packaging

material can be recycled.

2.4. INSTALLATION AND MAIN PARTS

Place the machine on a horizontal, stable and clean ground. Protect the machine from heavy

rain and burning sunshine. Check that there is enough space for cooling air circulation in front

of and behind the machine.

The serial number of the machine is marked on the machine CE-marking. Identificating the serial

number is the only proper means of maintaining and identifying parts for a specific product. It

is important to make correct reference to the serial number of the product when making repairs

or ordering spare parts.

2.4.1. Assembling the equipment

The equipment is assembled in the following order:

1. Transport unit P40/P40L

6185264/6185264L

2. Cooling unit Procool 30

6262016

Assembly the transport unit according to the instructions in the package. Fasten the cooling unit

to the transport unit by using the screws and bolts delivered with the equipment.

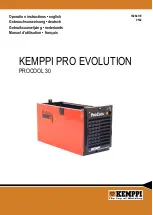

2.4.2. Main parts of cooling unit

2.3. SERIAL NUMBER

Front machine

A Housing

C Test switch

D Overheat control lamp

F Filling hole

Back side

G Mains voltage connection cable

H Control cable

I Cooling water output hose

J Cooling water input hose

This equipment’s electromagnetic compatibility (EMC) is designed for use in an

industrial environment. Class A equipment is not intended for use in residential location

where the electrical power is provided by the public low-voltage supply system.