Kelly Jaguar series KLS-N Sinusoidal Brushless PM Motor Controller User’s Manual

V1.21

33

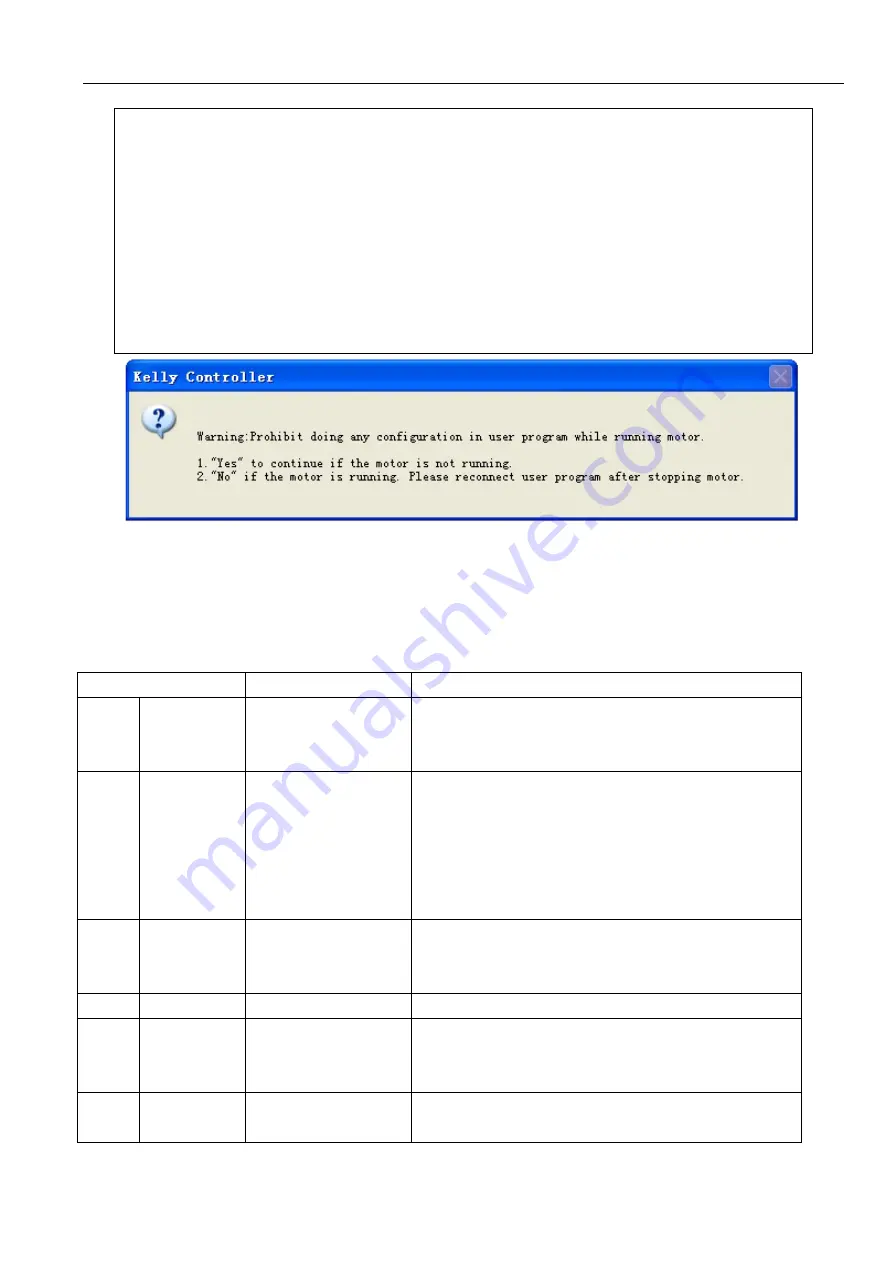

Caution:

•Make certain that the motor is connected before trying to run Identification angle

function in the configuration software. The controller needs to be connected to

batteries, motor and throttle before Identification operation. That is to say, it is not

enough to connect only power supply(PWR=pin7) to batteries for Identification Angle

operation.

•Configuration software will be regularly updated and published on the website. Please

Update your Configuration Software regularly. You must uninstall the older version

before updating.

•Please try to use Identify function for motor and hall sensors in the user program

Table 1: Error Codes

Buzzer Error Codes

Code

Explanation

Solution

1,1

¤ ¤

Automatic error

identification

1. Wrong wiring of motor phase line or hall.

Please suspend the motor when enable

Auto-Identify function.

1,2

¤ ¤¤

Over voltage error

2. Battery voltage is too high for the controller.

Check battery volts and configuration.

3. Regeneration over-voltage. Controller will have

cut back or stopped regen.

4. This only accurate to ± 2% upon Overvoltage

setting.

1,3

¤ ¤¤¤

Low voltage error

1. The controller will clear after 5 seconds if battery

volts returns to normal.

2. Check battery volts & recharge if required.

1,4

¤ ¤¤¤¤

Reserved

2,1

¤¤ ¤

Motor did not start

Motor did not reach 25 electrical RPM within 2

seconds of start-up. Hall sensor or phase wiring

problem.

2,2

¤¤ ¤¤

Internal volts fault

1. Measure that B+ & PWR are correct when

measured to B- or RTN.