6

2.3

Maintenance

Keep the machine in a dry place so the grinding wheels or belts will not risk getting any

damp or rain.

The grinding wheel will often get uneven because of use and therefore we recommend that

you level the grinding wheel off frequently. When the grinding wheel is worn more than 25%

we recommend that you change to a new wheel. An uneven grinding wheel causes

vibrations which with time will damage the bearings in the machine. Damaged tool rests,

eye shields and covers must be replaced to avoid personal damage.

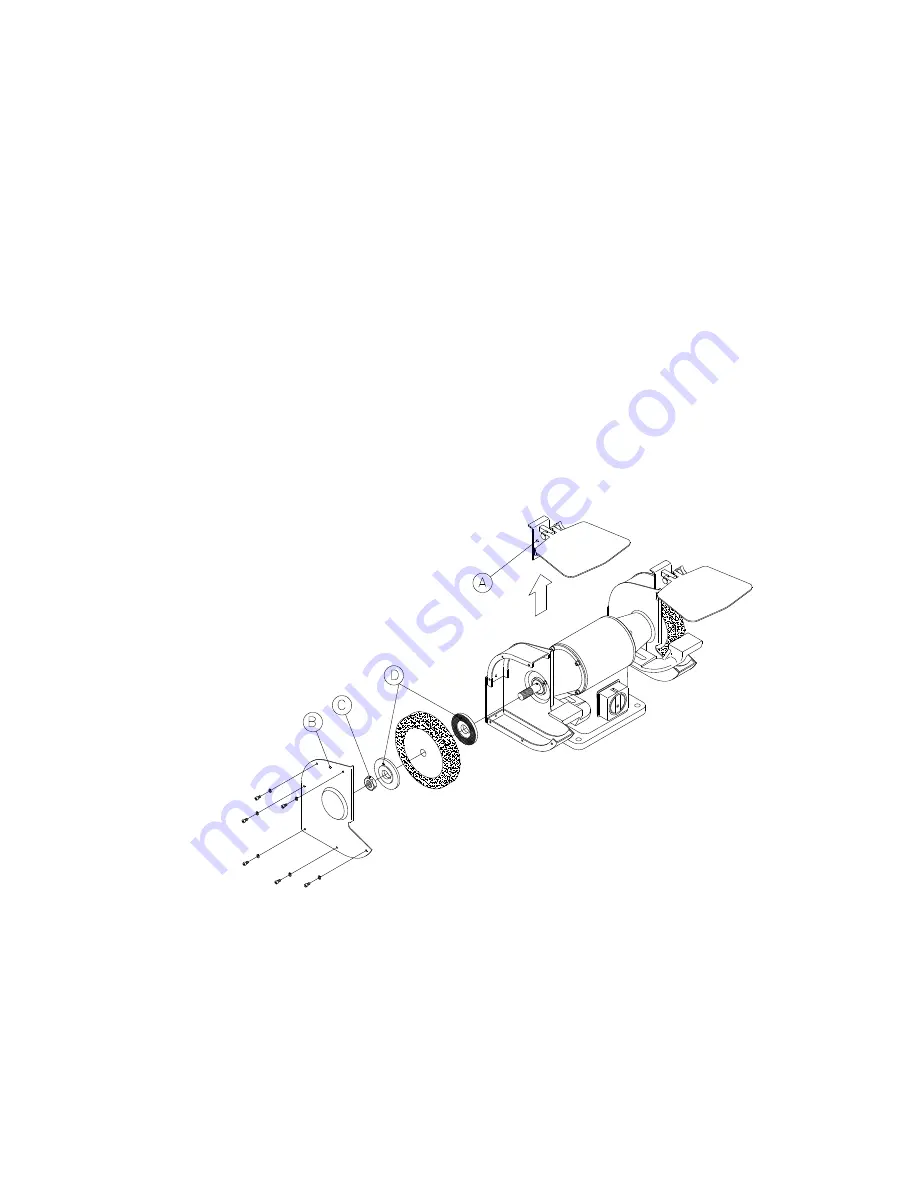

When to change the grinding wheel please dismount the spark arrester (A) (see

fig.: 2.1

),

then dismount the outer cover (B). The reverse nut (C) and the outer flange is to be

unscrewed, now the outer flange and the grinding wheel can be dismounted. The new

grinding wheel is not allowed to exceed the measures shown on the sign on the machine. It

is also very important that the hole dimension is correct.

The grinding wheels are provided with labels placed around the holes on both sides of the

grinding wheel. If these labels are missing or damaged they must be replaced by new ones

of the same dimension.

The new grinding wheel is to be mounted between the two flanges (D) and the reverse nut

(C) screwed on and fastened. The reverse nut (C) is to be fastened so tightly that it can

hold the grinding wheel tight but on the other hand it is not to be tightened too much as it

can cause unwanted stress in the grinding wheel.

Fig.: 2.1

Содержание PSD 5

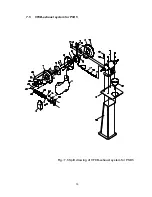

Страница 18: ...17 7 4 PSD 5 belt arm Fig 7 4 Split drawing of PSD 5 belt arm...

Страница 20: ...19 7 5 VFCB exhaust system for PSD 5 Fig 7 5 Split drawing of VFCB exhaust system for PSD 5...

Страница 27: ...26 Disa Switch w emergency stop 8 4...

Страница 28: ...27 8 5 PSD 5 connected to EX16 Dust Extraction...