122

11.3.3 Check

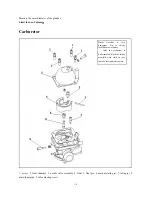

Check whether the needle valve assembly, needle valve seat and float assembly are abrasive or damaged.

Replace any abrasive or damaged needle valve core.

Replace the carburetor body if the needle valve seat

is abrasive.

Replace any abrasive float tongue.

Check whether the carburetor oil needle is

abrasive or damaged. If yes, replace it

and also the main jet.

Check whether the idle metering jet, main

metering jet and main jet are abrasive,

damaged or stained. If yes, replace it.

R

eplace any abrasive plunger.

Clean any stained carburetor or fuel pipes according

to instructions.

11.4 Installation and adjustment

Assemble or install it in reverse order.

Carburetor adjustment

Note:

the idle adjusting screw has been adjusted for the carburetor in factory, which needs no adjustment usually.

In disassembly, record the rotation number for installation.

Start and warm up for about 3 minutes to make the engine run at normal driving temperature.

Adjust the idle adjusting screw to make the engine run at 1800rpm;

Tighten the mixture adjusting screw to the extreme with moderate force;

Then the engine flames out (if not, check whether the air filter connecter is leaked, or screws are tightened or air

filter inlet is blocked);

Retreat the mixture adjusting screw by one circle;

Restart and adjust the idle adjusting screw to reach 2000-2500rpm;

Adjust the mixture adjusting screw (counter-clockwise) slowly until the engine reaches the maximum speed

Screw

Float chamber

Idle adjusting screw

Float pin

Needle valve assembly

Float

Main metering jet

Main foam pipe

Idling jet