3.2

3.2

Operation

Using the 5

°

Offset Cutter

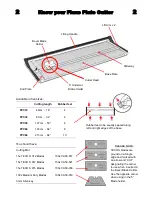

Sight Line Strip

Cutter Bar

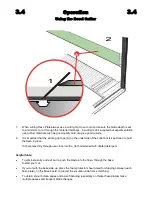

1.

The blade holder on the right hand side of the cutting head produces a 5° undercut. This enables

the flexo plate to be joined on the roller and leave no gap at the join. Without the undercut the

flexo plate will meet the base of the material but will leave a small gap at the outer surface of the

plate.

2.

The right hand edge of the cutter bar is fitted with a sight line strip. This gives an exact indication

where the blade will cut and therefore makes accurate alignment of the plate much easier.

When cutting, the bulk of the flexo plate should be on the left hand side, under the cutter bar, trim

the first edge with the waste on the right hand side of the cutline. Rotate the plate 180°

then trim

the second edge.

There are a number of different types of blade included with the cutter to allow for experimentation.

There are however a few general rules to bear in mind:

•

TECH S blades are ground on a Single edge and marked with an arrow and

‘

CUT

’

designating the

corner to use when inserted in the Bevel Blade Holder. Use the opposite corner when using in the

5°

Blade holder.

•

When using the single sided blades, the flat side of the blade should always be facing towards the

central part of the cutting head. Irrespective of which blade holder is used, when it is mounted in

the cutting head (as in 1.) the ground edge of the blade should be seen.

1

2