●

Set a minimum opening stroke of 50 mm to achieve sufficient velocity to trigger

the measurement.

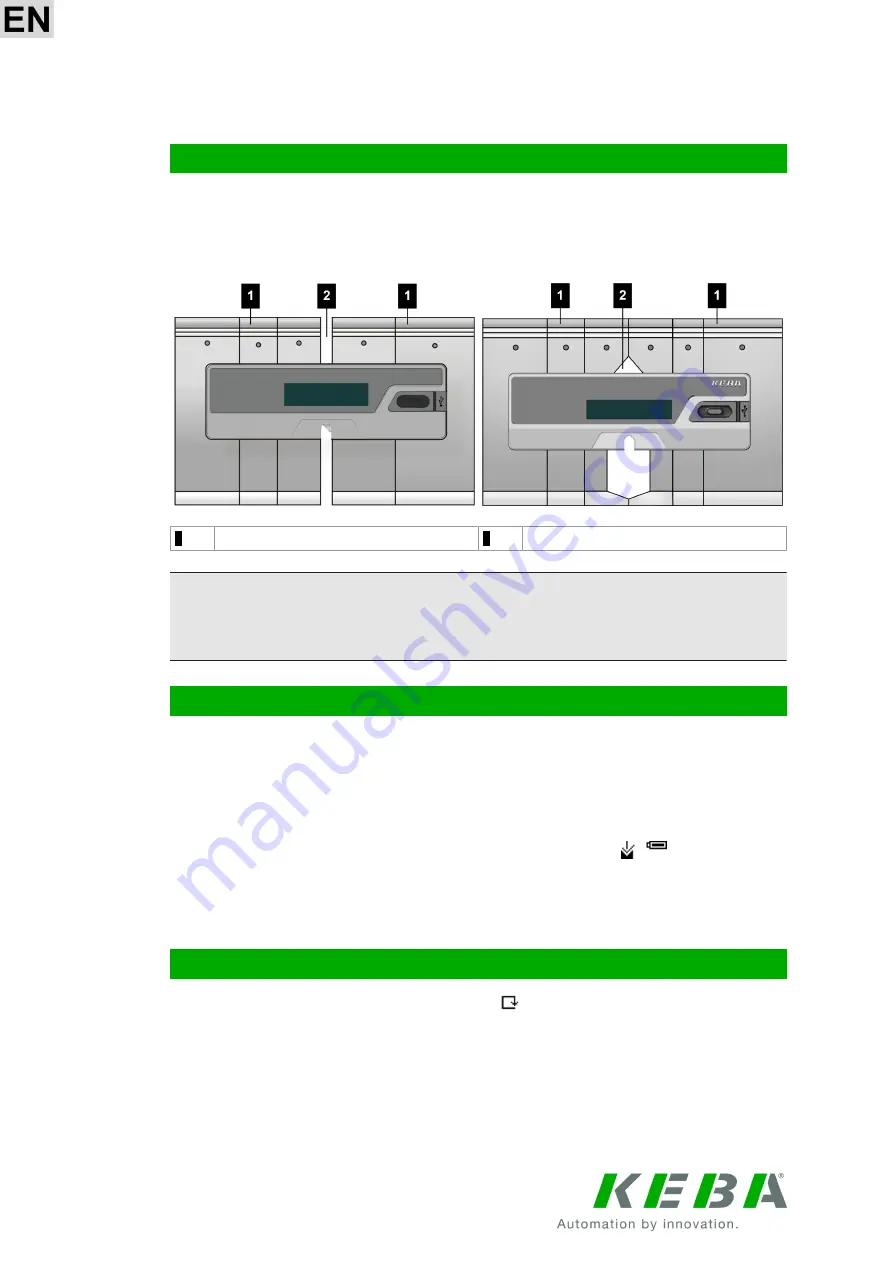

Installation on the upper tool

1) Create a gap of approx. 6 mm in the upper tool of the press brake.

2) Attach KeMes so that the laser beam can penetrate the gap unobstructed and

hit both legs of the workpiece at an angle of 90°.

3) Align the device symmetrically using the centering mark.

1

Stamp segments

2

Gap / recess

Information

For a correct measurement result, the device must be attached in parallel to the

bending edge and is allowed to be mounted only on vertical surfaces.

Measurement at the press brake (machine mode)

1) Attach the device to the upper tool.

2) Switch the device on by pressing the operating button.

3) Navigate to the

Machine

menu item by pressing and holding the operating but-

ton.

4) Start machine mode by pressing the operating button once.

5) Wait until the idle state has been reached (display shows"

").

6) Start the bending operation. The measurement operation starts automatically.

If there are too few individual measurement values, the displayed measurement

value will flash and could be incorrect.

Continuous measurement

1) Press and hold the operating button until

appears on the display.

2) Carry out the measurement.

The measurement can be terminated by pressing the operating button 2x briefly.

Содержание KeMes A1 Series

Страница 9: ...EU Declaration of Conformity...

Страница 10: ......

Страница 11: ...FCC Supplier s Declaration of Conformity...

Страница 12: ...FCC Supplier s Declaration of Conformity...