I&O manual

7

3

cm

/m

50m

m

50m

m

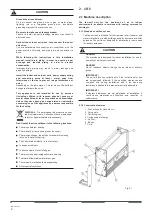

3.2.1 Hydraulic connections

Connection to the system

connect to the unit

condensate discharge

or defrosting tray.

IMPORTANT!

CAUTION

Fig.3-7

It is most important that the hydraulic connections are made

with great care by specialized fitters.

Connect the unit to the water system by means of the fittings which

are marked Flow and Return.

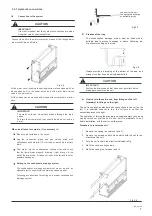

Creation of the trap

The condensation drainage system must be fitted with a

suitable trap to prevent seepage of odors. Following are

directions for setting up the trap.

Fig.3-8

Always provide a drainplug at the bottom of the trap, and

arrange it so that it can be quickly dismantled

Fig.3-6

IMPORTANT!

CAUTION

All the water coils, including the optional extras, are equipped with air

bleed-valves next to the upper union, and with water drain valves

need to the lower union.

All the valves can be opened and closed with screwdrivers or allen

keys.

CAUTION

IMPORTANT!

The water coils can be partially drained through the drain

valves.

To drain them completely, they should be blown out with an

air-jet.

When installation is complete, it is necessary to:

Position the drain-tube so that it does not put strain on the

drainage connector on the unit.

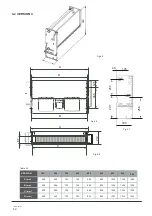

How to turn the coil round, from fittings on the left

(standard) to fittings on the right.

The unit is supplied as standard with connections to the coil on the

left. It is possible however to turn the coil round, so that the

connections are on the right.

The operation of turning the principal and supplementary coils round

can be carried out with the unit in situ, but it is preferable to do it

before installation, with the unit on solid ground.

Procedure to reverse the coil:

Bleed the air contained in the circuit.

Lag the connection pipes and any valves titted with

anticondensation material 10 mm thick or install the auxiliary

drain.

Pour water into the condensation collector tray and check

that the liquid drains properly, following it right through to the

exit of the drain tube. If it does not, check the fall and look for

possible blockages.

Setting up the condensate drainage system

The condensation drainage system must be set up with an

adequate fall, to ensure that the water escapes properly.

Following are directions for setting up a proper condensation

drainage system.

1 Remove the casing (on versions I and II);

2 Remove the screws on both sides which hold the coil to the

structure of the unit;

3 Turn the coil round in the direction indicated in Fig;

4 Re-fit the coil mounting screws;

5 Re-fit the casing (on versions I and II)

Fig.3-9

Содержание KFC-S-2T-250D

Страница 2: ......

Страница 16: ...MD15IU 015CW DZ1 16126200A06812 ...

Страница 17: ...I O manual 15 ...

Страница 18: ......

Страница 19: ...I O manual 17 ...

Страница 20: ......