Operating Manual

16

Original Operating Manual

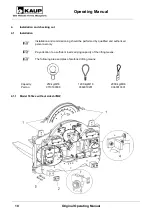

Failure of the safety devices (e.g. the pressure relief valve and the non-return

valve) and incorrect connection of the controls to the actuators can cause

malfunctioning of the attachment and damage to it.

After mounting and before initial operation, check the functions and the

identification of the attached equipment with the movement directions of the

operating elements (operating lever, joystick, etc.).

6.2

Significant modification

Significant modifications are, for example, those which affect the stability, performance, speed and

strength of components.

The EC Declaration of Conformity is invalidated by a significant modification of the attachment.

Modifications to the attachment may only be made with prior approval by the manufacturer.

6.3

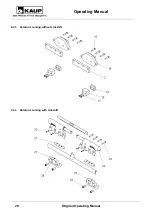

Schedule for routine maintenance and lubricants

Lubricants approved and recommended by KAUP

Greases

Note

Lithium soap grease

NLGI Class 2

e.g. Avialith 2

Designation DIN51825:

K 2 K-30

Complex soap grease

NLGI Class 2

e.g. Turmogrease Gel M 5

Foundry quality

Teflon spray

e.g. Wieds or Rivolta

Only for plastic sections

Hydraulic oil

Series gear box 80

e.g. Avia Gear RSX 680, DIN 51517

Filling capacity 0,5 l

Series gear box 125

Filling capacity 1,8 l

Series gear box 200

Filling capacity 9,5 l

Special gear box 80

e.g. Klüber Syntheso, D460 EP

0520990019

Special- gear box 125

0520990075

The specified maintenance schedules can change as a result of the operating conditions

such as extreme cold, heat and dust or poor ground conditions and this must be taken

into account by the owner.

With other loads, such as fork arms with a length of over 2.400 mm or raised load

centres, amended/shorter maintenance intervals should be agreed by the user with the

manufacturer.