Operating Manual

Original Operating Manual

21

As necessary

Version 1

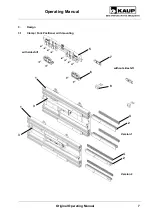

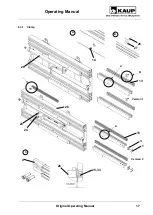

: Replace worn sliders (13) by removing nut (25) see chapter 6.3.2 - from

each cylinder (26). Pull the slides (34) to the side to remove

– see chapter 6.3.2 -.

Remove the greasing nipples (14) and screw (26). Replace the sliders (13). When

installing the new sliders, make sure that the axial stops (27) are correctly seated.

Remount the screw (26) and the greasing nipple (14). Push the slides (34)

– see

chapter 6.3.2 - into clamp body (28) and reinstall nuts (25) of cylinders (26).

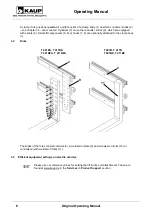

Version 2

: Replace worn sliders (13), by removing screws (1), safety metal sheet (3),

screws (2), safety metal sheet (4) and nut (25)

– see chapter 6.3.2 – from each

cylinder (26). Pull the slides (34) to the side to remove

– see chapter 6.3.2 -. Replace

the sliders (13). Push the slides (34)

– see chapter 6.3.2 - into clamp body and

remount the safety metal sheet (4) with screw (2), safety metal sheet (3) with screws

(1) and nut (25) of cylinders (26).

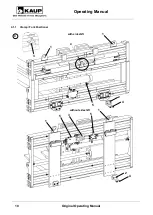

Replace worn sliders (15), by removing hooks (10). Lift the attachment off the fork

carriage of the lift truck. Replace the sliders (10). When installing the new sliders (15),

make sure that the sliders (15) are correctly seated in the sideshifter housings (8).

Place the attachment on the fork carriage and remount the hooks (10) with screws

(9).

Replace defective supporting rollers (18) in the hooks (10) by removing the screws

(9). Using suitable lifting equipment, tilt the complete equipment forwards off the fork

carriage of the lift truck and secure this position. Using suitable means remove the

fixing pin (29), bolt (30), holder (31) and fixing pin (32). Replace the supporting roller

(18). Mount the fixing pin (32), holder (31), bolt (30), fixing pin (29) and hooks (10)

using screws (9).

Renew the faulty cylinder (26) by removing the hydraulic lines from the cylinder (26)

with the hydraulic system depressurized. Remove the nut (25)

– see chapter 6.3.2 -

and nut (33). Replace the cylinder (26). Reinstall the nuts (33, 25) and the hydraulic

lines.

After installing or removing a cylinder (26), always check the clearance between the

cylinder mount and nuts (25, 33) of the cylinder (26). Cylinders are installed with axial

clearance of 1.5 to 2 mm.

Bent forks are not safe to operate and their continued use should be prevented.

Straightening of forks may only be performed by the manufacturer of the fork or by

one of his authorised workshops.

You can increase the service life of forks by using forks especially protected

against wear.