20

OPERATION OF THE SYSTEM

WTC 600 LP / MP

Service Handbook 08.2004

3

Operation of the System

3.1

Assembly and Starting Operation

Assembly

Chapter

Checking the scope of delivery (delivery note)

Placing the equipment in the set-up location and positioning

Connecting the untreated water to the WTC 600 LP/MP; connecting

2.2, 3.3.2.1, 3.3.1

the WTC 600 PI in between, if required (depending on delivery scope)

Installing the piping for backwashing and drinking water

2.2

Installing the float switch

3.3.2.4

Filling and connecting the sand filter and the activated carbon filter

3.4.2

Connecting the electrical system

SLP, 3.3.2

Table 8

Assembly work to be carried out upon starting operation

Starting Operation

Chapter

Establishing the untreated water supply

2.2

Manually actuating the sand filter backwashing

3.4.2

Manually actuating the activated carbon filter backwashing

3.4.2

Flushing the reverse osmosis

3.4.3.7

Filling the chemicals container

3.2

Adjusting the flow rates

3.4.3.8

Filling out the metering table in the operating instructions

Instructing the operator (operating instructions)

Table 9

Overview of start-up work

A water analysis with the following values must exist for commissioning of the WTC 600:

- Total hardness GH in °dH

- Iron Fe in mg/l

- Manganese Mn in mg/l

- Ammonium NH

4

or NH

3

in mg/l

- System yield determined by the sales department (Normal case: 75%, in special cases 50%).

Содержание WATERCLEAN 600 CD

Страница 1: ...Service Handbook 5 905 521 08 2004 Waterclean 600 CD LP MP PI 1 024...

Страница 6: ...WTC 600 LP MP 6 Service Handbook 08 2004...

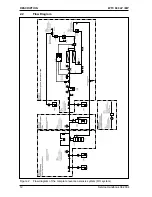

Страница 64: ...64 APPENDIX WTC 600 LP MP Service Handbook 08 2004 RO control program structure Figure21...

Страница 65: ...65 WTC 600 LP MP APPENDIX Service Handbook 08 2004...

Страница 66: ...66 APPENDIX WTC 600 LP MP Service Handbook 08 2004 RO 1000 Manual Control System RO 1000 MANUAL...