English

Operating Manual – Snowthrower

25

Troubleshooting

Risk of injury from starting the

machine by mistake

Before doing any work on this

machine

– Turn off the engine.

– Remove the ignition key and the

spark-plug connector.

– Wait until the engine has cooled

down.

Caution

Faults encountered when operating

the machine sometimes have simple

causes which you can remedy

yourself. If you are in any doubt, or if

expressly instructed to do so, seek

the help of a specialist workshop.

Have repair work carried out only by

a specialist workshop which will use

original replacement parts.

!

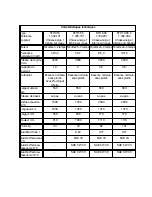

Fault

Possible cause

Action to take

Engine does not start.

Fuel tank empty.

Fill fuel tank.

Fuel has gone stale.

Drain out stale fuel into a suitable container in

the open air

1

). Fill up tank with clean, fresh

fuel.

Engine is cold.

Choke lever is not set to “

”/“ON”.

Set choke lever to “

”/“ON”.

Throttle lever is not set to “

”

(STH 5.56, STH 8.66, STH 10.66 C)

.

Set throttle lever to “

”.

Spark-plug connector not connected.

Put spark-plug connector on the spark plug.

Air filter dirty.

Clean air filter

1

).

Spark plug dirty or defective.

Clean spark plug

1

).

Have defective spark plug replaced

2

).

Carburettor flooded.

Set choke lever to “OFF” and start engine.

Engine runs unevenly

(stutters).

Choke lever set to “

”/“ON”.

Set choke lever to “OFF”.

Spark-plug connector loosely connected.

Connect spark-plug connector firmly.

Stale fuel.

Water or dirt in the fuel system.

Drain off stale fuel into a suitable container in

the open air

1

).

Fill up tank with clean, fresh fuel.

Vent hole in fuel filler cap blocked.

Clean fuel filler cap and vent hole.

Air filter dirty.

Clean air filter

1

).

Carburettor altered.

Have carburettor reset

2

).

Machine does not clear snow.

Shear bolts broken off.

Put in new shear bolts (see “Replacing a shear

bolt”).

Worm or throw-out chute blocked.

Stop engine, disconnect spark-plug connector.

Eliminate blockage.

Coupling cable for worm drive not correctly

adjusted.

Adjust coupling cable (see “Adjust coupling

for the worm drive”).

V-belt slack or torn

(STH 953)

.

Tighten slack V-belt (see “Tightening the V-

belt”). Have torn V-belt replaced

2

).

V-belt slack or torn

(STH 5.56, STH 8.66,

STH 10.66 C)

.

Have slack V-belt tightened

2

).

Have torn V-belt replaced

2

).

Содержание STH 953

Страница 2: ...STH 5 56 1 335 101 STH 8 66 1 335 201 STH 10 66 C 1 335 302 STH 953 1 332 101...

Страница 4: ......

Страница 5: ......

Страница 128: ...130 STH 953 STH 5 56 STH 8 66 STH 10 66 C 16 o 1 2 1 2 2 1 STH 953...

Страница 129: ...131 STH 5 56 STH 8 66 STH 10 66 C 1 STH 10 66 C STH 10 66 C 4 1 I II III STH 8 66 8 1 3 2 1 2 3 STH 953 11 1 2 3...

Страница 133: ...135 10 25 50 1 3 9 3 4 1 2 1 2 2 1 2 3 5 4 25...

Страница 136: ...138 2 3 4 1 y...

Страница 137: ...139 1 Choke ON Choke ON STH 5 56 STH 8 66 STH 10 66 C 1 1 2 Choke OFF Choke ON Choke OFF 1 1 2...

Страница 160: ...STH 953 162 1 2 1 2 3 A B 2x 1x 1x C 1x D...

Страница 161: ...STH 953 163 1 2 D A B 2x 1x 1x 1x C D A B B C...

Страница 162: ...STH 5 56 164...

Страница 163: ...STH 5 56 165...

Страница 164: ...STH 5 56 166...

Страница 165: ...STH 5 56 167 A A B B C C D D D E F 2x 6x 6x 4x 2x 2x...

Страница 167: ...STH 8 66 STH 10 66 C 169 R R R R 4x U U U M F U 4x blue L P Q L 2 3 2x L 2 1 M 4x V 2x P P 2x D 2x Q 1x...

Страница 168: ...STH 8 66 STH 10 66 C 170 E 3x G H J K L 2x 2x 6x 1x 1x P 6x 1 1 2 K E P K E P 1 2 4 360 360 360 G 3 5cm 5cm...

Страница 169: ...STH 8 66 STH 10 66 C 171 1 2...

Страница 170: ...STH 8 66 STH 10 66 C 172 A A B B C C D D D E F 2x 6x 6x 4x 2x 2x...