-

8

m

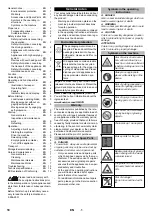

DANGER

Risk of explosion!

Î

Only use batteries with terminal cover.

Restore terminal cover in the event of

loss.

m

DANGER

Risk of explosion!

Î

Do not place tools or similar items on

the battery. Risk of short-circuit and ex-

plosion.

m

DANGER

Risk of injury!

Î

Ensure that wounds never come into

contact with lead. Always clean your

hands after working on batteries.

m

DANGER

Risk of fire and explosion!

Î

Smoking and naked flames are strictly

prohibited.

Î

Rooms where batteries are charged

must have good ventilation because

highly explosive gas is emitted during

charging.

m

DANGER

Danger of causticization!

Î

Rinse thoroughly with lots of clear water

if acid gets into the eye or comes in con-

tact with the skin.

Î

Then consult a doctor immediately.

Î

Wash off the acid If it comes in contact

with the clothes.

Normally, the machine is equipped with a

maintenance-free battery.

1

Positive terminal

2

Terminal cover

3

Negative terminal

Î

Insert battery in battery mount.

Î

Screw on mounts on battery base.

Î

Connect pole terminal (red cable) to

positive pole (+).

Î

Connect pole terminal to negative pole

(-).

Î

Attach the pole covers.

Î

Check that the battery poles and pole

terminals are adequately protected with

pole grease.

CAUTION

Risk of damage!

Î

Regularly check the fluid level in acid-

filled batteries.

Î

Unscrew all cell caps.

Î

Take a sample from each cell using the

acid tester.

–

The acid in a fully charged battery has a

specific weight of 1.28 kg/l at a temper-

ature of 20 °C.

–

The acid in a partially discharged bat-

tery has a specific weight between 1.00

and 1.28 kg/l.

–

The specific weight of the acid must be

uniform in all cells.

Î

Put the acid sample back into the same

cell.

Î

Where fluid level is too low, top up cells

to the mark provided with distilled wa-

ter.

Î

Charge battery.

Î

Screw in cell caps.

m

DANGER

Risk of injury!

Î

Comply with safety regulations on the

handling of batteries. Observe the di-

rections provided by the manufacturer

of the charger.

m

DANGER

Risk of damage!

Î

Charge the battery only with an appro-

priate charger.

Î

Unscrew all cell caps.

(only with low-maintenance battery)

Î

Connect positive terminal cable from

the charger to the positive pole connec-

tion on the battery.

Î

Connect negative terminal cable from

the charger to the negative pole con-

nection on the battery.

Î

Plug in mains connector and switch on

charger.

Î

Charge battery using lowest possible

level of charging current.

Î

When the battery is charged, first re-

move the charger from the mains and

then disconnect it from the battery.

Î

Screw in cell caps.

(only with low-maintenance battery)

Î

Disconnect pole terminal to negative

pole (-).

Î

Disconnect pole terminal to positive

pole (+).

Î

Loosen the mounts on battery base.

Î

Remove the battery from the battery

holder.

Î

Dispose of the used battery according

to the local provisions.

m

DANGER

Risk of injury!

Î

Always apply the safety rod when the

waste container is raised.

Î

Perform the safeguarding only from

outside the hazard zone.

1

Holder of safety rod

2

Brake fluid container

3

Closing head

Î

Move up the waste container and se-

cure it by means of the safety rod, see

Chapter "Emptying the waste contain-

er"

Î

Check if the there is enough brake fluid

in the brake fluid reservoir.

Note

The filling level has to be between Min.

and Max.

Î

If necessary, refill DOT brake fluid cur-

rently commercially available.

m

DANGER

Risk of burns!

Î

Allow engine to cool down.

Î

Wait for at least 5 minutes after switch-

ing off the engine before checking the

engine oil fill level.

Fire, sparks, open light, and

smoking not allowed!

Danger of causticization!

First aid!

Warning note!

Disposal!

Do not throw the battery in the

dustbin!

Installing and connecting the battery

Check and correct the fluid level of the

battery (only with low-maintenance

battery with cell caps)

Charging battery

Remove the battery

Checking the brake fluid level and

topping up brake fluid

Check engine oil level and top up, if

required

(1

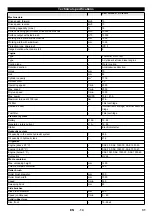

Содержание KM 130/300 R D Classic

Страница 2: ......