TIP

Assembly, installation and operating instructions

36

10

Maintenance

10.1 Securing against reconnection

DANGER!

Risk of death by unauthorised or uncontrolled restart!

Unauthorised or uncontrolled restarting of the equipment can result in serious injury or death.

Before restarting, ensure that all safety devices are fitted and working properly and that there is no haz-

ard to humans.

Always follow the procedure described below to prevent accidental restart:

1. de-energise.

2. Prevent accidental re-connection.

3. Check that the equipment is de-energised.

4. Cover and cordon off adjacent live parts.

WARNING!

Risk of injury from rotating parts!

The fan impeller can cause severe injuries.

Switch off the unit and prevent it from reconnection before commencing any work on moving compon-

ents of the fan. Wait until all parts have come to a standstill.

10.2 Maintenance Schedule:

The sections below describe maintenance work needed for the proper and trouble-free operation of the equipment.

If there are signs of increased wear during regular checks, shorten the required maintenance intervals to the actual wear and

teat. Contact the manufacturer with any questions about maintenance work and intervals.

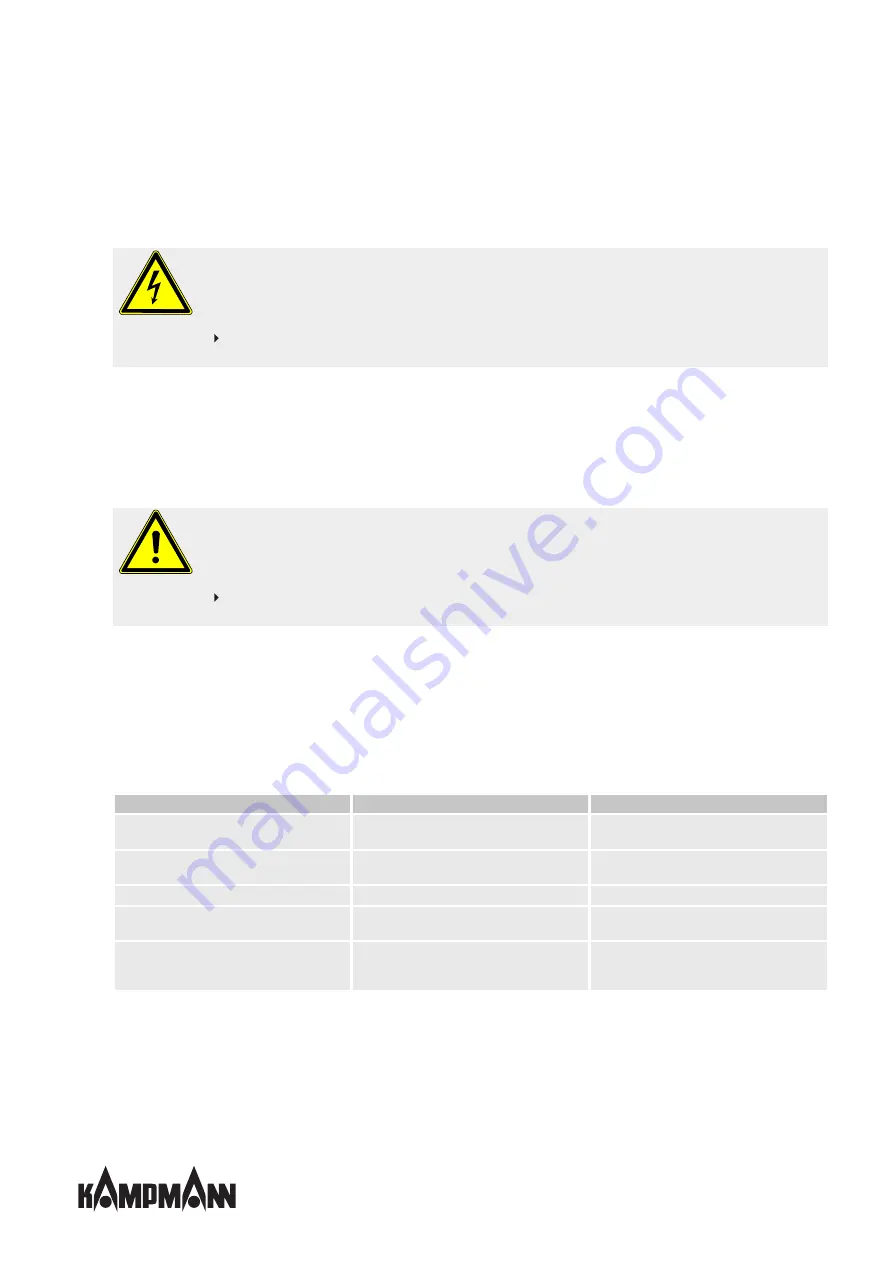

Interval

Maintenance task

Personnel

As required

Regular visual checks and acoustic checks for

damage, dirt and function.

User

every six months

Check water-side connections, valves and fit-

tings for dirt, leak-tightness and function.

User

every six months

Check the electrical wiring.

Qualified personnel

every six months

Clean components/surfaces that come into con-

tact with air.

Qualified personnel

quarterly

Check the heat exchanger for dirt, damage, cor-

rosion and leak-tightness. Carefully vacuum the

heat exchanger if dirty.

User

10.3 Clean the inside of the unit

Check all elements that come into contact with air (internal surfaces of the unit, outlet elements etc.) for dirt or deposits dur-

ing maintenance and use a commercially available product to remove.

Содержание TIP

Страница 2: ......

Страница 40: ...TIP Assembly installation and operating instructions 40 12 Certificates...

Страница 45: ......

Страница 46: ......

Страница 47: ......