PaGE 12

KrP PrEP taBlEs

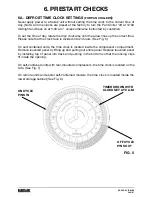

A thermometer is provided on all prep table refrigerator and freezer cabinets.

Allow cabinet and pan chiller to reach normal operating temperature before loading

(approximately 1 hour). Frosting of pan chiller plates is normal.

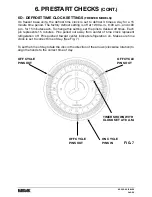

Thermostats are provided to independently control the temperature of the pan chiller and

the lower storage cabinet. The pan chiller system has been supplied with a time clock

for automatic defrost.

notE: Pan cHIllEr sYstEM Must BE PErIoDIcallY sHut DoWn For

ProPEr DEFrost anD FunctIonInG oF tHE unIt. (SEE INSTRUCTIONS FOR

SETTING DEFROST TIME CLOCK).

7a - Pan cHIllEr

To insure proper food temperatures are maintained in exposed insert pans, the following

conditions are recommended:

1. No direct air blowing on food product from other equipment in the kitchen.

2. Room ambient temperatures of 86°F or less around working area of pan chiller.

3. Food sits a minimum of 1 inch below top of insert pan.

4. All shelving mounted over insert pans (with heated equipment above it) must be

insulated.

5. Occasional stirring of certain foods may be required in order to maintain consistent

temperatures.

6. Some food products chill faster than others i.e., lettuce, diced tomatoes, etc. Double

pans will help prevent over chilling.

7. For remote refrigerators with pan chiller systems, it is imperative that the existing

refrigeration equipment must be sized properly and in good working condition.

7B - loWEr storaGE caBInEt

The lower storage cabinet is designed to maintain temperatures between 33°F and 40°F

for refrigerated bases, or –2°F to 2°F for freezer bases. If the base is overloaded with

warm food products, a certain amount of time is required to remove heat from items

before operating temperatures can be maintained. The system is designed for storage of

refrigerated or frozen product. Frequently opening the doors or drawers will increase the

temperature in the cabinet and will require a certain amount of time to recover.

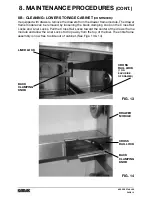

7c - sHutDoWn For EXtEnDED PErIoDs

If the prep table and lower storage cabinet are not to be used for an extended period

of time, disconnect the electrical power supply and open the doors (or drawers) to the

lower storage cabinet. As soon as the divider bars have defrosted and the cabinet has

warmed to room temperature, wipe out the pan chiller cavity and base interior.

Do not HosE DoWn or Pour WatEr or lIQuID clEanErs In tHE Pan

cHIllEr coMPartMEnt as tHIs coulD causE DaMaGE to tHE Pan cHIllEr

anD rEQuIrE an autHorIzED sErVIcE tEcHnIcIan to rEPaIr. FaIlurE to

FolloW tHIs InstructIon WIll VoID WarrantY. (FOR PROPER CLEANING

PROCEDURES SEE “MAINTENANCE PROCEDURES”).

7. oPEratIon

Содержание KRP

Страница 23: ...NOTES...