Precautions On Reassembling

When reassembling, also refer to the

disassembling procedures.

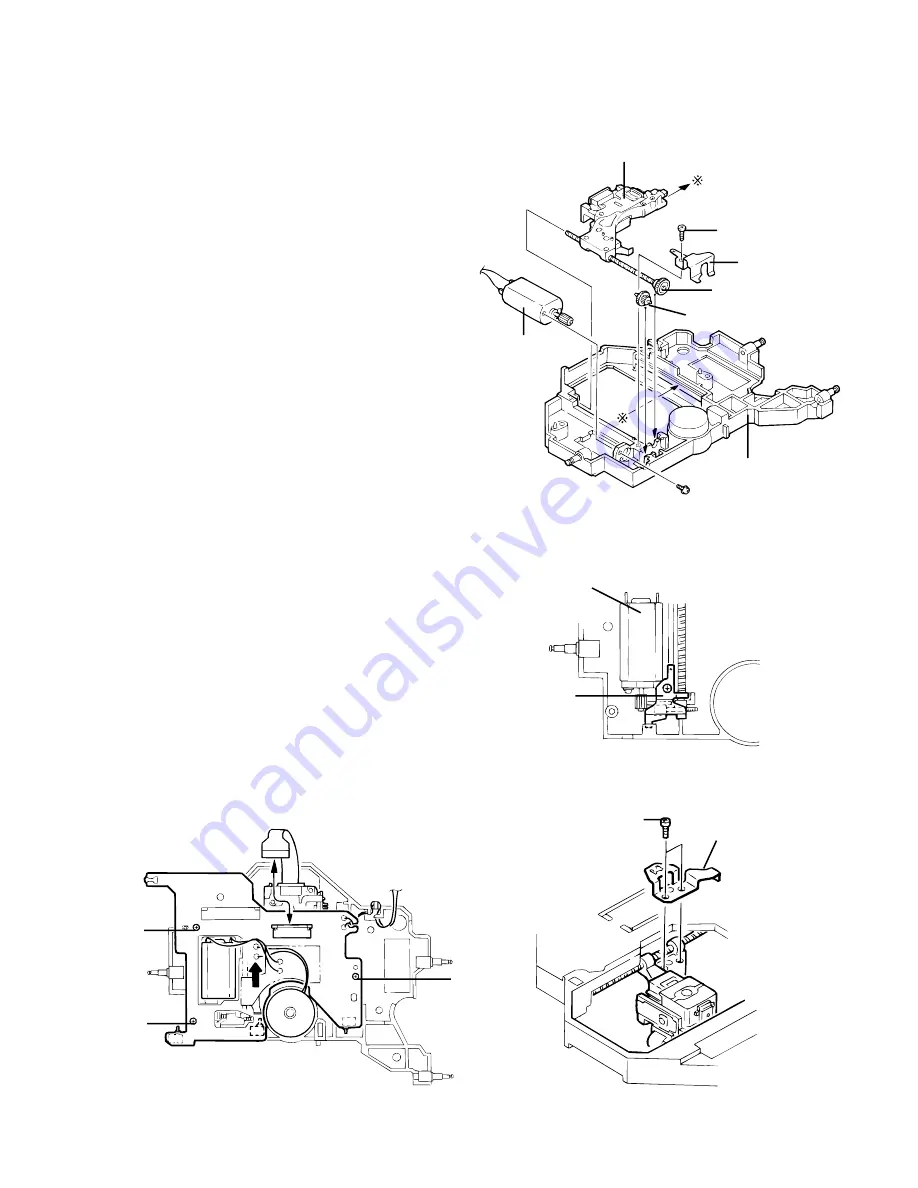

Mounting the Traverse Mechanism

1. When mounting the pickup assembly, attach the feed slide

shaft assembly to the traverse chassis.

Apply E-JC-525 grease to the shaft.

2. Mount the middle gear and the feed slide shaft to the traverse

chassis and secure them with the screw (14) through the

shaft holder.

3. Before mounting the mechanism PCB assembly, move the

pickup to the outer edge position, then secure the PCB

assembly using the screw (15).

At this time, check that the rest switch is correctly placed.

4. To mount the rack arm, first move the pickup to the middle

position and secure it with the screws (16).

Fig. 34

Fig. 33

Fig. 32

Fig. 31

Pickup Assembly

Attached to chassis

Shaft Holder

Feed Slide Shaft (half

coated with grease)

Middle Gear

Motor

Chassis

Mounting the

Feed Motor Assembly

Feed Motor

Shaft Holder

Spindle Motor

Mechanism PCB Assembly

Rack Arm

Move the pickup to the

middle position

15

15

15

16

14

1‑11