–

54

–

Standard Adjustment

Results of lmproper Adjustment

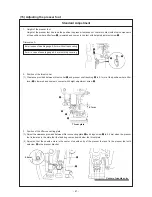

1. Inspection and replacement

Loosen setscrews

3

in the oil filter cap and remove oil filter cap

2

.

Draw out oil filter

1

to inspect it. When it is clogged with dust,

replace it with a new one.

After the replacement, fix oil filter cap

2

with setscrews

1

in the oil

filter cap.

(Caution)

When removing the oil filter cap

2

, lubricating oil

collected in oil filter

1

will leak out. So, be careful.

2. Oil circulation identification

(1) In case the oil does not come out from oil circulation identification

window

4

even when oil filter

1

is replaced with a new one, remove

six setscrews

6

in the oil pan, remove oil pan

5

, and tilt the machine

head to the rear up to the position where pipe connecting joint screw

9

can be removed.

(2) Oil sucked up from gear pump

7

passes oil pipe

8

and enters oil filter

1

from pipe connecting joint screw

9

. When the lubricatin oil does not rise

to oil circulation identifacation window

4

, The hole in pipe connecting

joint screw

9

may be clogged with dust. So, check it.

(Caution)

When there is any foreign material in oil pan

5

, remove it.

™

In case oil cannot be observed from

oil circulation identification window

4

even when the sewing speed is 2,500

rpm or over, the machine will be in

danger of seizure if the operation is

continued.

7

9

8