– 1 –

❷

❸

❶

❹

❻

❺

INSTALLATION

Congratulations on your purchase of a JUKI's window-plate-mounting type Auto lifter.

The main features of this device are as follows: 1) Simple installation, 2) Usable in combination with the knee lifter.

Please read these instructions to assure long-term satisfactory usage.

1. Press the OFF button of the power switch to turn OFF

the power after confirming that the sewing machine

has stopped.

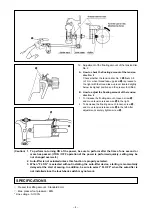

3. Remove the side plate.

Remove setscrew

❸

. Remove wire clamping base

❶

and oil shield

❷

both of which are secured with

the same screw. (This oil shield

❷

is not used to

install the AK device.) After you have removed oil

shield

❷

, fix wire clamping base

❶

at its home posi-

tion by means of setscrew

❸

.

(Caution) The floating amount of the tension disc

is changed by loosening wire clamping

base

❶

. After the assembly of the AK-85,

check the floating amount of the tension

disc and adjust if necessary. (Refer to

Adjustment of the floating amount of the

4. Replace the hinge screw of the knee lifter horizontal

bar and the hinge screw of the knee lifter link with

horizontal bar pin

❹

and hinge screw

❺

supplied with

the unit. Install knee lifter link spring

❻

as illustrated

in the figure.

2. Check to make sure that the power switch is in the OFF

state. Then, unplug the power cord.Perform the work

of step 3. after confirming that the power has been cut

and it has passed for 5 minutes or more.

1

4

2

0

3

Содержание AK85B

Страница 1: ...i ENGLISH INSTRUCTION MANUAL AK85B ...