– 4 –

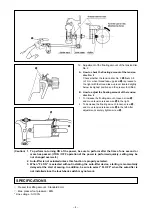

12. Adjustment of the floating amount of the tension disc

No. 2

A.

How to check the floating amount of the tension

disc No. 2

Check whether the tension disc No. 2

floats 0.5

to 1 mm when thread take-up picker

is pressed to

the right with the thread take-up lever located slightly

below its highest position and the presser foot lifted.

B.

How to adjust the floating amount of the tension

disc No. 2

1. To increase the floating amount, loosen screw

,

and move tension release wire

to the right.

2. To decrease the floating amount, loosen screw

,

and move tension release wire

to the left. After

adjustment, securely tighten screw

.

(Caution) 1. To perform re-turning ON of the power, be sure to perform after the time of one second or

more has passed. (If ON / OFF operation of the power is performed quickly, setting may be

not changed over well.)

2. Auto-lifter is not actuated unless this function is properly selected.

3. When “FL ON” is selected without installing the auto-lifter device, starting is momentarily

delayed at the start of sewing. In addition, be sure to select “FL OFF” when the auto-lifter is

not installed since the touch-back switch may not work.

SPECIFICATIONS

○

Presser foot lifting amount : Standard 9mm.

○

Max. presser foot pressure : 88N.

* Line voltage : At 100%

Содержание AK85B

Страница 1: ...i ENGLISH INSTRUCTION MANUAL AK85B ...