3

Installation

ADVICE!

Extending the support surface in the direction of travel

is permitted and can reduce the load on components.

The vehicle manufacturer is responsible for the specification and

strength of the weld seams and any positioning of the rotating axle

outside the recommended zone.

All welding work must be performed solely by expert personnel.

The relevant, currently valid standards and codes of practice must

be observed.

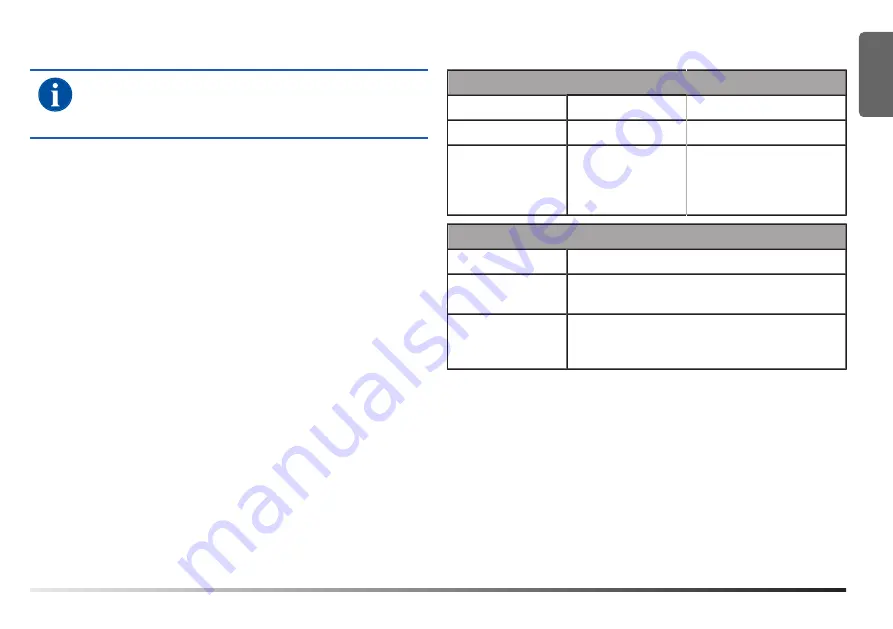

See the following table for approved filler metals and welding con-

sumables.

Approved filler metals

Welding process EII

MAG C, MAG M

Filler metal

Electrode rod

Welding wire

Name of stan-

dard

ISO 2560 - A -

E 35 0 A5

ISO 14341 - A -

G 42 0 M(C) G3Si1

ISO 14341 - A -

G 42 0 M(C) G4Si1

Approved welding consumables

Welding process EII

Welding consum-

ables

Electrode rod

Name of stan-

dard

ISO 14175 -C1

ISO 14175 -M21

ISO 14175 -M24

EN

Twist Locks R 403 Fx

MUB 013 005 M30

(REV-B)

07-2020

7