English

– 15

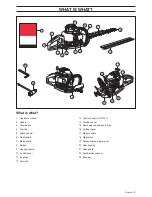

MAINTENANCE

Carburetor

Your Jonsered product has been designed and manufactured

to specifications that reduce harmful exhaust fumes. The

engine will be run in after it has used 8-10 tanks of fuel. To

ensure that the engine runs at peak performance and

produces as little harmful exhaust fumes as possible after the

running-in period, ask your dealer/service workshop (which

has a rev counter for this purpose) to adjust your carburettor.

Function

•

The carburetor governs the engine’s speed via the throttle

control. Air and fuel are mixed in the carburetor. The air/

fuel mixture is adjustable. Correct adjustment is essential

to get the best performance from the machine.

•

The setting of the carburetor means that the engine is

adapted to local conditions, for example, the climate,

altitude, fuel and the type of 2-stroke oil.

Adjusting the idle speed

The T-screw regulates the throttle setting at idle speed. If the

T-screw is turned clockwise this gives a higher idle speed;

turning it anti-clockwise gives a lower idle speed.

Before any adjustments are made, make sure that the air filter

is clean and the air filter cover is fitted.

Adjust the idle speed with the idle adjustment screw T, if

adjustment is necessary. First turn the idle adjustment screw

T clockwise until the blades start to move. Then turn the idle

adjustment screw T anticlockwise until the blades stop. The

idle speed is correctly adjusted when the engine runs

smoothly in every position. There should also be a clear

margin to the speed at which the blades start to move. The

blades must also remain stationary when the choke control is

in the start throttle position.

Muffler

CAUTION!

Some mufflers are fitted with a catalytic

converter. See chapter on Technical data to see whether your

machine is fitted with a catalytic converter.

The muffler is designed to reduce the noise level and to direct

the exhaust gases away from the operator. The exhaust

gases are hot and can contain sparks, which may cause fire

if directed against dry and combustible material.

Some mufflers are equipped with a special spark arrestor

screen. If your machine has this type of muffler, you should

clean the screen at least once a week. This is best done with

a wire brush.

On mufflers without a catalytic converter the screen should be

cleaned weekly, or replaced if necessary. On mufflers fitted

with a catalytic converter the screen should be checked, and

if necessary cleaned, monthly.

If the screen is damaged it

should be replaced.

If the screen is frequently blocked, this

can be a sign that the performance of the catalytic converter

is impaired. Contact your dealer to inspect the muffler. A

blocked screen will cause the machine to overheat and result

in damage to the cylinder and piston. See also instructions

under the heading Maintenance.

CAUTION!

Never use a machine with a defective muffler.

!

WARNING! The complete clutch cover and

gear housing must be fitted before the

machine is started, otherwise the clutch may

come loose and cause personal injury.

!

WARNING! If the idle speed cannot be

adjusted so that the cutting attachment

stops, contact your dealer/service

workshop. Do not use the machine until it

has been correctly adjusted or repaired.

T

!

WARNING! Mufflers fitted with catalytic

converters get very hot during use and

remain so for some time after stopping. This

also applies at idle speed. Contact can result

in burns to the skin. Remember the risk of

fire!

Содержание HT 2124

Страница 21: ......

Страница 22: ... z RAo 5c z RAo 5c ...

Страница 23: ......

Страница 24: ... z RAo 5c 2007 01 30 z RAo 5c 1150337 95 ...