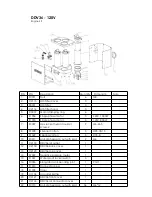

Pre-filter

Loosen the 3 clamps and remove the top. Take the bag from the new filter.

Lift out the filter and place it gently in a plastic bag. This bag must be properly disposed.

Insert a new filter.

Important:

If you are removing the Pre-filter in order to clean it. Hitting the filter with force or use of

compressed air will destroy the filter. It can handle water, but high pressure water

cleaning will destroy it.

HEPA Filter

Loosen the two nuts on each filter cover cap. Carefully lift the filter into a clean plastic

bag, use the bag from the new filter. This bag must be properly disposed. Insert a new

filter in reverse order.

Important:

HEPA filters can’t be cleaned, trying this might destroy it. When installing the

replacement filter, make sure to not touch the inside of the filter. Any kind of

force/damage on the inside of filter media will destroy the new filter.

8. SERVICE

When cleaning and servicing the machine, you must switch off the machine and

remove the plug from the outlet.

Avoid cleaning with a high pressure cleaner. If necessary, do not direct at the

openings on the machine, especially the opening for cooling air.

Before moving the machine from the work area, the machine must be cleaned.

All other equipment must be regarded as contaminated and be treated

thereafter.

If possible, use a special suitable room.

Proper personnel protective equipment must be used. Dust can be spread when

the coarse filter and the absolute filter are replaced that can be hazardous to

health. Accordingly, the user should wear protective glasses, protective gloves,

and a breathing mask conforming to protection class FFP3.

All parts which are contaminated after service must be properly disposed of in

plastic bags according to all regulations.

If the machine has to be used for other purposes, it is extremely important that the

machine is cleaned, to avoid the spread of hazardous dust.

Do not puncture the HEPA filter. Risk of dust dispersion.

9. WARRANTY

All

DDV

devices and accessories have a 12-month factory warranty counting from the

manufacturing date on the machine. Do not attempt to repair the suction apparatus

without the consent of the manufacturer.

The warranty does not cover defects which are the result of normal wear and tear,

negligence, defective use, unauthorized repair or the suction apparatus being connected

to the incorrect voltage.

In the event of any complaint, the suction apparatus or an agreed part of it must be

returned to us or our authorized representative for warranty examination and for any

warranty repair or replacement.

WARNING

Remember to switch off the machine and pull the plug out of the outlet before servicing.

Содержание DYNAMIC DIAMOND DDV36

Страница 1: ...DYNAMIC DIAMOND VACUUM DDV36 Vacuum Manual ...

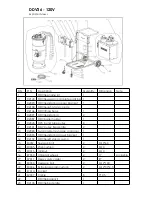

Страница 12: ...DDV36 120V Dustbin kit ...