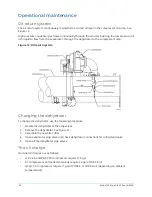

Operational maintenance

Oil return system

The oil return system continuously maintains the correct oil level in the compressor oil sump. See

Figure 12.

High pressure condenser gas flows continuously through the eductor inducing the low pressure, oil

rich liquid to flow from the evaporator, through the dehydrator to the compressor sump.

Figure 12: Oil return system

Changing the dehydrator

To change the dehydrator, use the following procedure:

1. Isolate the dehydrator at the stop valves.

2. Remove the dehydrator. See Figure 12.

3. Assemble the new filter-drier.

4. Open evaporator stop valve and check dehydrator connections for refrigerant leaks.

5. Open all the dehydrator stop valves.

The oil charge

Nominal oil charges are as follows:

•

H, K1-K4, and P8-P9 YK compressors require 17.5 gal

•

K7 compressors on flooded shell units require 24 gal of YORK K oil

•

Q3-Q7 YK compressors require 11 gal of YORK K or YORK H oil (depending on ambient

temperatures)

Model YK Style G R-134a or R-513A

26

Содержание York OptiView YK G Series

Страница 2: ...2 Model YK Style G R 134a or R 513A...

Страница 10: ...Figure 3 Refrigerant flow through chiller falling film evaporator Model YK Style G R 134a or R 513A 10...

Страница 11: ...Figure 4 Refrigerant flow through chiller flooded evaporator 11 Model YK Style G R 134a or R 513A...

Страница 21: ...Figure 10 System components rear view 21 Model YK Style G R 134a or R 513A...

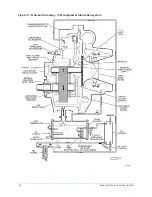

Страница 22: ...Figure 11 Schematic drawing YK compressor lubrication system Model YK Style G R 134a or R 513A 22...