JOHNSON CONTROLS

18

FORM 50.40-OM1 (713)

ISSUE DATE: 07/17/2013

SECTION 2 - OPERATION

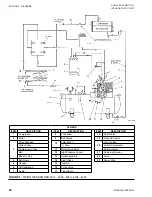

TABLE 8 -

PRESSURE DIFFERENCE FOR DE-

TERMINING PRESENCE OF NON-CONDENSIBLE

GASES

REFRIGERANT

DIFFERENCE BETWEEN GAUGE

READING AND SATURATED

PRESSURE

PSIG

KPA

CFC-11

4

27.6

CFC-114

4

27.6

HFC-123

4

27.6

CFC-12

6

41.4

HFC-134a

6

41.4

CFC-500

8

55.1

HCFC-22

10

69.0

CFC-502

10

69.0

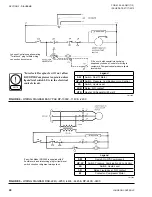

CHARGING REFRIGERATION UNIT WITH

REFRIGERANT FROM RSR UNIT

Gas Charging

When it is time to transfer the refrigerant from the RSR

to the refrigeration unit, the latter must first be charged

with gas.

This is particularly true of refrigeration units contain-

ing liquid coolers and/or water cooled condensers. If

liquid refrigerant is charged in the unit when the unit

pressure is lower than the saturation pressure equiva-

lent to 32°F (0°C), the water tubes can freeze and burst

even though water is being pumped through the tubes.

Set the water flow and valves as shown in column 4

. When the valves are set, refrig-

erant gas will flow into the refrigeration unit because

of the higher pressure in the RSR. The RSR compres-

sor does not have to run during gas charging.

When the refrigeration unit pressure is above the satu-

ration pressure equivalent to 32°F (0°C) (Table 8) or

when the pressure has equalized, close all of the valves.

On RSR Models 1100 and 1600 and on Easy Tank™

Models RT 1100 and 1600, an electric heater is in-

stalled on the bottom of the storage vessel to increase

the pressure of the stored refrigerant when the RSR is

subjected to low ambient temperatures.

Charging with Liquid Refrigerant

Set the valves and pumps as indicated in column 5 of

. Turn the toggle switch on the RSR to the

ON position.

Refrigerant vapor will be pulled off of the top of the refrig-

eration unit condenser, raised to a higher pressure by the

RSR compressor, condensed to liquid in the RSR conden ser,

and then returned to the refrigeration unit as a liquid.

The level of liquid in the storage vessel can be observed

through the sight glasses in the vessel. When the liquid has

been exhausted from the storage vessel, close valves 6 and

7 and simultaneously shut OFF the RSR toggle switch.

Removal of Refrigerant from Hoses and Storage

Vessel

Before removing the hoses between the RSR and the

refrig eration unit, open valves 1 and 3 on the manifold

and close valves 2 and 4. Start the RSR compressor and

open valve 7 simultaneously. Valve 5 should be open

and valve 6 closed.

Run the RSR compressor until a vacuum of at least

29 in. Hg. exists in the storage vessel. At this point,

close valve 7 and simultaneously move the RSR toggle

switch to the OFF position. Close manifold valves 1, 2,

3, and 4, as well as valve 5. The hose valves can then

be closed and the hoses removed from the refrigeration

unit.

TABLE 9 -

VAPOR PRESSURE – CFC-11, CFC-12,

CFC-22 AND CFC-500

TEMP.

(°F)

VAPOR PRESSURE*

CFC-11 CFC-12 CFC-22 CFC-500

-150

29.9

29.6

29.4

-140

29.9

29.4

29.0

-130

29.9

29.1

28.4

-120

29.9

28.6

27.7

-110

29.8

28.0

26.5

-100

29.8

27.0

25.0

26.4

-90

29.7

25.7

23.0

24.9

-80

29.6

24.1

20.2

22.9

-70

29.4

21.8

16.6

20.3

-60

29.2

19.0

12.0

17.0

-50

28.9

15.4

6.2

12.8

-40

28.4

11.0

0.5

7.6

-35

28.1

8.4

2.6

4.6

-30

27.8

5.4

4.9

1.2

-25

27.4

2.3

7.4

1.2

-20

27.0

0.6

10.2

3.2

-15

26.5

2.4

13.2

5.4

-10

26.0

4.4

16.4

7.8

-5

25.4

6.7

20.1

10.4

0

24.7

9.2

24.0

13.3

Содержание YORK EASYTANK LD17584

Страница 4: ...JOHNSON CONTROLS 4 FORM 50 40 OM1 713 ISSUE DATE 07 17 2013 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 28: ...JOHNSON CONTROLS 28 FORM 50 40 OM1 713 ISSUE DATE 07 17 2013 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 48: ...JOHNSON CONTROLS 48 FORM 50 40 OM1 713 ISSUE DATE 07 17 2013 LD17572 Figure 16 COMPRESSOR PARTS 51VSM ...