JOHNSON CONTROLS

13

FORM 50.40-OM1 (713)

ISSUE DATE: 07/17/2013

2

SECTION 2 - OPERATION

GENERAL

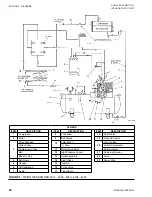

The function of a Refrigerant Recovery/Recyling Unit

(RSR) is to remove and store refrigerant from any

machine using the refrigeration cycle and CFC or

HCFC refrigerants. The refrigerants must be removed

from the refrigerant circuit before opening any part of

the unit for maintenance or repairs. Federal law prohib-

its the venting of refrigerant to the atmosphere.

The RSR is con nected to the refrigeration unit by means

of hoses supplied with the RSR. The RSR compressor

develops a pressure differential between the RSR and

the refrigeration unit so that liquid refrigerant is forced

into a storage vessel used in conjunction with the RSR.

The RSR is equipped with a water cooled condenser

that is used to condense the refrigerant vapor remain-

ing in the refrigeration unit after the liquid refrigerant

has been removed. For this duty, the RSR compressor

pumps the remaining vapor through the condenser and

the resulting liquid refrigerant flows into the storage

vessel.

After the refrigeration unit has been repaired, the pro-

cess is reversed so that refrigerant is pumped back into

the refrigeration unit.

PRIOR TO STARTING REFRIGERANT

RECOVERY

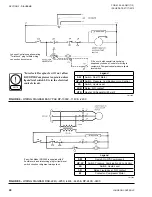

Set Pressure Safety Control

A high/low pressure safety control is wired in the mo-

tor control circuit. The pressure settings are adjustable

to con form to the design working pressure of the RSR

storage ves sel and the upper limit for satisfactory

TABLE 5 -

SETTINGS FOR PRESSURE SAFETY CONTROL SWITCHES

REFRIGERANT

CUT OUT

CUT IN

HIGH PRESSURE

LOW PRESSURE

HIGH PRESSURE

LOW PRESSURE

PSIG

KPA

IN HG

KPA

PSIG

IN

H

G

KPA

CFC-12/HFC-134a

150

1034

20

68

Manual Reset

10

34

CFC-500

180

1241

20

68

Manual Reset

10

34

CFC-502

250

1724

20

68

Manual Reset

10

34

HCFC-22

250

1724

20

68

Manual Reset

10

34

CFC-11/HFC-123

10

69

29

98

Manual Reset

20

68

CFC-114

30

207

29

98

Manual Reset

20

68

performance of the RSR condenser and compressor for

the refrigerant being recovered.

Prior to starting the RSR unit, the pres

sure control must be set to the high and

low pressure values shown in

Check Oil Level

RSR Compressor (High Pressure Units)

The oil level should be checked in the sight glass lo-

cated in the RSR compressor crankcase.

A shortage of oil will result in the failure

of the RSR compressor.

The oil level should be 1/2 to 3/4 from the bottom of

the sight glass when the RSR compressor is not run-

ning.

All units, Except where Refrigerant 134a is used, come

factory charged with YORK Type “C” oil. Only this

type of oil should be used when adding oil with the ex-

ception where R-134a is used in the refrigeration unit.

The Ester based oil is used in conjunction with R-134a.

Consult the manufacturer’s recommendations for oil to

be used in the RSR compressor if R-134a is used in the

refrig eration system.

It is recommended that an RSR unit be dedicated for

use in recovering only R-134a. Otherwise the oil in

Содержание YORK EASYTANK LD17584

Страница 4: ...JOHNSON CONTROLS 4 FORM 50 40 OM1 713 ISSUE DATE 07 17 2013 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 28: ...JOHNSON CONTROLS 28 FORM 50 40 OM1 713 ISSUE DATE 07 17 2013 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 48: ...JOHNSON CONTROLS 48 FORM 50 40 OM1 713 ISSUE DATE 07 17 2013 LD17572 Figure 16 COMPRESSOR PARTS 51VSM ...