437642-UIM-C-0210

14

Johnson Controls Unitary Products

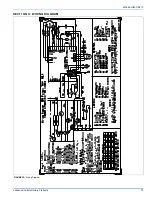

FIGURE 19:

Thermostat Chart - Single Stage HP with Single Stage Furnaces

Single Stage Heat Pump – Single Stage Furnace with Hi-Efficiency Motor

C

24 – Volt Common

R

24 – Volt Hot

Y1

First Stage Compressor

O

Reversing Valve

Energized in Cool

L

Malfunction Light

G

Fan

*DP32H70124

THERMOSTAT

W1

Second Stage Aux. Heat

E

Emergency Heat

W2

Third Stage Heat

N/A

*BP21H50124

*BN21H00124

*DP21H40124

*DN21H00124

THERMOSTAT

N/A

*DN22U00124

THERMOSTAT

Part Numbers:

SAP = Legacy

67297 = 031-01975

E*B*

E*ZD

E*R*

OD MODELS

*HGD

HP*

*RHS

O

Reversing Valve

Energized in Cool

C

24 – Volt Common

R

24 – Volt Hot

W1/66(out)

Heat

Y

Compressor

DEMAND DEFROST

CONTROL

X/L

Malfunction Light

W

Auxiliary Heat

SINGLE STAGE

HEAT PUMP

1

1

Part Number:

S1-2HU16700124

2

24VAC Humidifier

(Optional)

External Humidistat

(Optional)

Open on Humidity Rise

2

Y2

Second Stage Compressor

Step 9 of Thermostat

Installer / Configuration

Menu must be set to

Pump OFF

Step 1 of Thermostat

Installer / Configuration

Menu must be set to

Heat Pump 1

TM8X

ID MODELS

C

24 – Volt Common

R

24 – Volt Hot

W

Full Stage Heat

SINGLE STAGE

FURNACE

G

Fan

SINGLE STAGE

FURNACE

Y/Y2

Full Stage Compressor

TMLX