JOHNSON CONTROLS

9

FORM 130.13-NOM8 (1021)

Cooling/Heating Medium Connections

Coils are male sweat connection. Use appropriate

brazing alloy for system temperature and pressure.

Refer to equipment construction submittal drawing for

specific connection size.

MAXIMUM HYDRONIC COIL

OPERATING PRESSURE MUST NOT EXCEED 450

PSIG.

In the event that leaking or defective components are

discovered, the Sales Representative must be notified

BEFORE any repairs are attempted. All leaks should be

repaired before proceeding with the installation.

Valves must be secured and supported to avoid damage

to coil headers. All valves, pipes, and components must

be sufficiently supported to ensure structural integrity

and proper operation of the unit.

After system integrity has been established the piping

should be insulated in accordance with the project

specifications. ALL chilled water and drip pan piping

not located over drip pans must be insulated to prevent

damage from sweating. This includes factory and field

piping inside the unit cabinet.

The drain should always be connected and piped to an

acceptable disposal point. For proper moisture carry-off,

the drain piping should be sloped away from the unit

at least 1/8” per foot. A drain trap may be required by

local codes and it is strongly recommended for odor

containment.

If necessary, you can change hot water coil connection

handing on one and two row coils from left-hand to right-

hand (and vice-versa) by rotating the coil “like a steering

wheel” 180° about its central axis when facing the fins.

NOTE: When the coil is flipped, the vent will no longer

perform in a vent capacity. It is suggested that valve

packages are re-oriented during this process to bring

the valve actuator back to its original position.

Piping Connections

Toxic residues and loose particles

resulting from manufacturing and

field piping techniques such as joint

compounds, soldering flux, and metal

shavings may be present in the unit

and the piping system. Special con

-

sideration must be given to system

cleanliness when connecting to solar,

domestic or potable water systems.

Submittals and Product Catalogs detailing unit

operation, controls, and connections should be

thoroughly reviewed BEFORE beginning the connection

of the various cooling and/or heating mediums to the

unit All accessory valve packages should be installed

as required, and all valves should be checked for proper

operation.

If coil and valve package connections are to be made

with “sweat” or solder joint, care should be taken to

assure that no components in the valve package are

subjected to a high temperature which may damage

seals or other materials. Many two-position electric

control valves, depending on valve operation, are

provided with a manual-opening lever. This lever should

be placed in the “open” position during all soldering or

brazing operations. Valve bodies should be wrapped

with a wet rag to help dissipate heat encountered during

brazing. Use a brazing alloy to make connections. Soft

solder is not recommended.

If the valve package connection at the coil is made with

a union, the coil side of the union must be prevented

from twisting (“backed up”) during tightening to prevent

damage to the coil tubing. Over-tightening must be

avoided to prevent distorting the union seal surface

and destroying the union. In the case of field installed

valves and piping, the chilled water valve cluster should

be installed in such a way that any dripping or sweating

is contained in the auxiliary drip pan or other device.

Valves should be secured or supported to avoid damage

to coil headers.

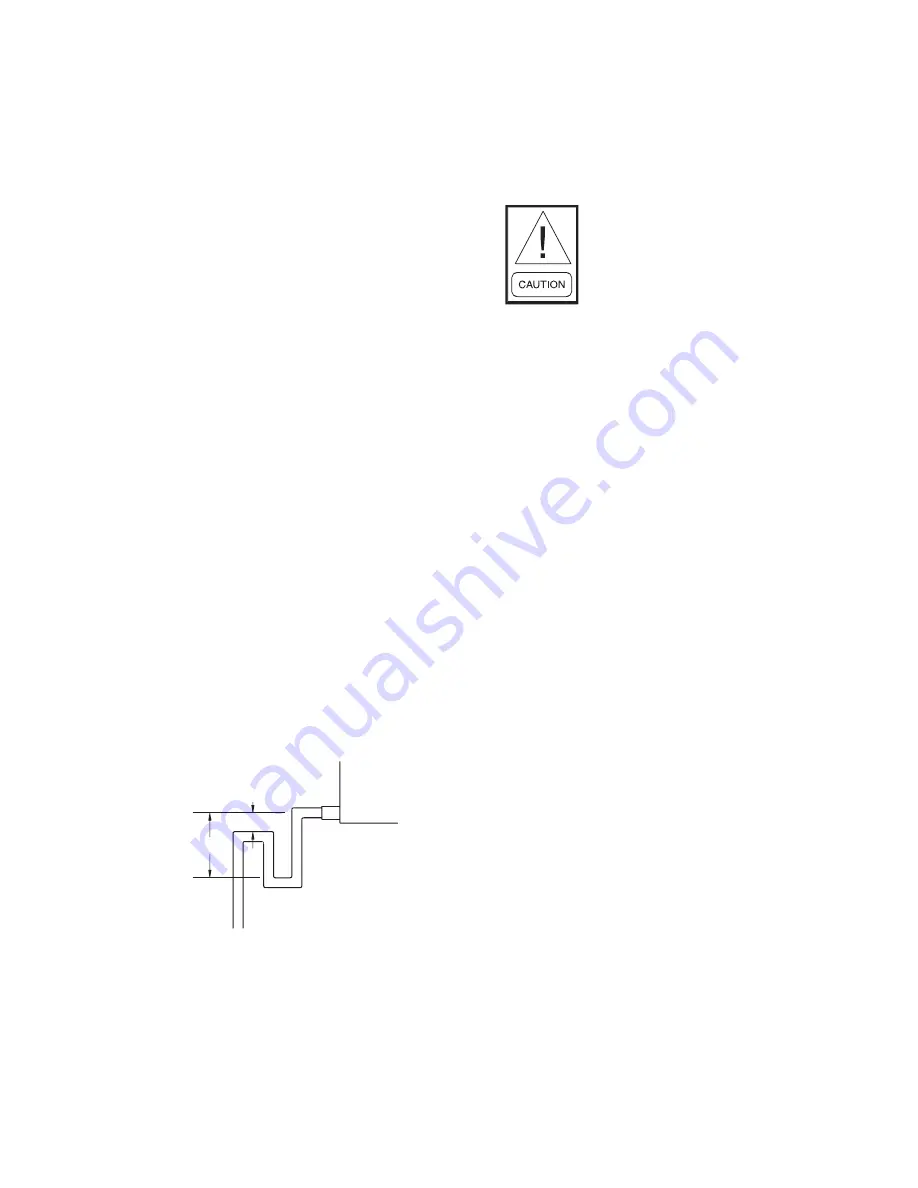

“H” MUST BE AT LEAST

1 INCH PLUS CASING

STATIC PRESSURE

H

X

“X” MUST BE AT

LEAST 1 INCH

Condensate Trap

Trap detail for positive cabinet

static pressure