XL EVAPORATIVE COOLING PRODUCTS

INSTALLATION

S140-600 IOM (NOV 07)

Page 4

INSTALLATION TOOLS

To complete the installation of the XL Evaporative Condens-

ers, the following tools are needed:

•

Drift

pins

• 8-foot straight edge

•

Level

• Assorted open-end wrenches

•

Socket

set

• Belt tension gage

•

Tape

measure

GENERAL INFORMATION

All XLC and XLP models should be anchored directly to

concrete pads or concrete piers. These units may also be

supported on structural “I” beams as outlined below.

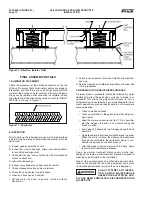

The Centrifugal Fan XLC units are designed to be sup-

ported by two structural “I” beams, one located under each

end of the unit and running the full width of the unit (See

Figure 1a).

The Vane Axial Fan XLP units are designed to be supported

by two structural “I” beams, one located under the front and

one under the rear of the unit, running the full length of the

unit (Figure 1b).

As an alternate, the structural “I” beams may run the full

width of the unit. Please refer to the unit foundation drawings

furnished by

Frick

for each specifi c sales order for complete

details.

Figure 1b - XLP I-Beam Location On Unit

Figure 1a - XLC I-Beam Location On Unit

adequate/loose fi eld wiring/connections. All personnel must

lock out and tag machinery before working on the condenser.

Proper safety precautions such as the use of insulating

soles/gloves and a trained “lookout buddy” are indispensable.

Ice formation in cold weather can present fall/slip hazards.

Icing safety procedures should be mandatory when the daily

ambient temperature falls below 40°F (4.4°C).

Water Chemistry

– All evaporative-cooled condensers op-

erate on principles that encourage biological growth in the

recirculating water unless effective treatment is applied. Re-

circulating water must be periodically analyzed for biological

culture plate counts. XL units should not be operated without

an effective biological treatment program.

NOTE: Emergency “shock” treatment with chemical bio-

cides may upset the unit’s appropriate pH range (creating

an excessively corrosive environment for the materials

of construction) and may expose operators to strong

chemicals that are corrosive or otherwise dangerous

if mishandled (see water treatment comments in the

CHEMICAL TREATMENT section of MAINTENANCE).

Field Piping Considerations for XL Unit Installation

– All

IDC units require strongly supported and anchored fi eld pip-

ing. No fi eld piping is to be supported by the XL itself. Wind

loading, temperature variation, etc., must be considered to

allow for movement between the tower, building, optional

vibration isolator/rails, and fi eld piping. A qualifi ed cooling

system design engineer should provide fi nal fi eld-piping

plans and specifi cations.

Before fi nalizing piping installation plans, it is recommended

that related plans for cooling system/plant expansion be

discussed with your fi eld piping/system designer and Imeco

sales representative. Incorporating pipe openings/sizes now

allows for easier installation in the future.

Each beam should be sized in accordance with standard

engineering practices, 55% of the operating weight of the

unit as a uniform load on the beam, allowing for a maximum

defl ection of 1/360 of the length, not to exceed 1/2 inch.